Custom Electric Tricycle Cargo Truck

Dive deep into the intricate details and custom specification options of the electric cargo truck. Choosing the right model tailored for your market can be daunting, but as a leading electric cargo tricycle manufacturer in China, AGL is here to guide you every step of the way. Discover the expertise behind our commitment and learn how to select the perfect match for your needs with our comprehensive insights.

Table Of Contents For This Page

To make sure you can find the information about all aspects of custom 3 wheel electric cargo tricycles you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

Styles of Electric Trike Cargo Vehicles

Detachable components for container loading, saving on transportation space.

Detachable components for container loading, saving on transportation space.

Driving System: Powering the Electric Cargo Tricycle

The drivetrain is the powerhouse of the electric tricycle. A well-engineered drivetrain provides efficient power transfer, ensuring optimal performance across various terrains and load conditions.

Motor Details

- Brushed Motors: Traditional and cost-effective but tend to be less efficient and require more maintenance than brushless types.

- Brushless Motors: More efficient with a longer lifespan. They offer better torque at low speeds, making them especially suitable for cargo tricycles.Currently, all electric vehicles produced by our factory use brushless motors for power under 2000W.

key Parameters of the Motor

Motor Power Recommendation:The choice of motor power and type directly influences the tricycle's efficiency and overall performance

| Rated Power (W) | Recommended Usage Scenarios |

|---|---|

| 250W to 500W | Suitable for flat terrains and lighter loads. These motors generally require a less-capacity battery, which can be lighter and more cost-effective. Ideal for urban settings where steep inclines are rare and cargo loads are moderate. |

| 500W to 1000W | A versatile range for varying terrains, including mild inclines. They demand batteries with higher capacity, which translates to increased weight but also longer range and better performance under load. Suitable for both urban and peri-urban |

| 1000W to 1500W | Designed for challenging terrains and heavier loads. These motors need high-capacity batteries, which can be heavier and pricier. These are often seen in tricycles meant for serious cargo transport, possibly in hilly areas or rough terrains. |

| 1500W to 2200W | Ideal for demanding applications that require transporting very heavy loads or navigating steep inclines consistently. They necessitate batteries with very high capacity, resulting in an even heavier overall vehicle weight. However, they offer unmatched power and torque, ensuring performance is not compromised even in the toughest conditions. |

| 2200W and Above | These are performance-oriented motors, suitable for specialized tricycles that need extreme power. Whether it's for towing, hauling unusually heavy loads, or operating in extreme conditions, these motors are equipped to handle it. They will require the most robust and high-capacity batteries, often adding significantly to the cost, but ensuring top-tier performance and reliability. |

Maximum Torque (Nm): Torque is the "force" needed to start a vehicle or climb a hill

Consider torque as the “muscle” of the electric motor, especially when starting the electric three-wheeler loader or climbing slopes.

Higher torque values mean the trike can handle steeper inclines and heavier loads without overstraining the motor. It’s like having a strong friend help you push a heavy cart up a hill. On flat terrain, moderate torque is sufficient, but if you plan to frequently traverse hilly areas or carry heavy goods, you will need a motor with high torque to ensure smooth and efficient operation.

Even with the same power motor, the torque can be different, and thus the performance of the electric three-wheeler loader will also vary.

Generally, the larger the motor, the higher the wattage, and the greater the torque it can produce. There isn’t a significant price difference between 800W and 1000W motors during selection, but there is a difference in weight and size. A larger motor can produce more torque, so especially in poor road conditions, the performance of a 1000W motor will be better.

Speed (RPM): Rotation speed determines the vehicle's top speed

A higher RPM generally implies a higher top speed when riding the electric tricycle, but in actual use, it is also influenced by factors such as the transmission system, vehicle weight, and load.

Choose AGL, and we will guide you in selecting the complex motor power and types, ensuring your vehicle achieves optimum efficiency and performance.

Controller Details

The controller acts as the brain of the drivetrain, ensuring the motor receives the right amount of current based on throttle input. It plays a pivotal role in determining acceleration and top speed.

Protection Functions: Such as overcurrent, low voltage cutoff, and overheat protection.

key Parameters of the Controller

Maximum Current (A): Determines the peak power the controller can provide to the motor.

Voltage Range (V): Matched with battery voltage.

Classified by Voltage: The voltage values are 36V, 48V, or 60V, 72V etc., among which 60V is the most common.

Classified by the number of power transistors: There are 15, 17, 18, 24, 36, etc. different numbers. The more the number of power transistors, the larger the matched motor power, leading to stronger output power, higher price, and greater power consumption.

Choosing a controller with the appropriate specifications, we can ensure the motor receives the correct current, optimizing the acceleration and top speed of the electric cargo tricycle.

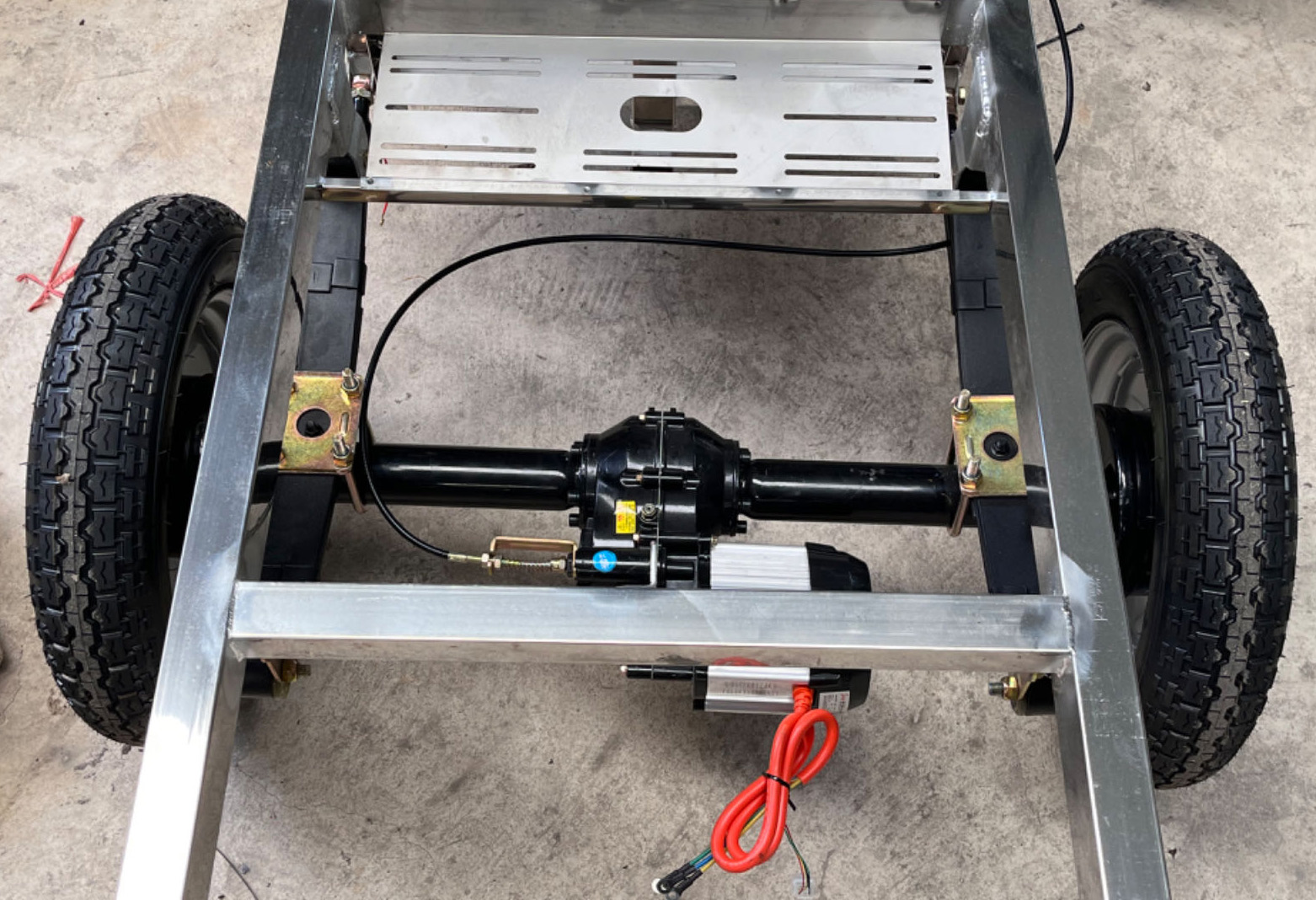

Transmission Details

Gear Drive

Usage: Predominantly used in over 95% of cargo electric tricycles.

Pros:

- Widespread Adoption: This is the most common and conventional method of power transmission in electric cargo tricycles.

- Dependable: Reliable for consistent power transmission to the wheels.

- Location: Incorporated within the rear axle of the tricycle, featuring a gear box.

Cons:

- Maintenance: May require periodic checking and maintenance to ensure optimal functioning.

- Complexity: Replacements or repairs may require specialized knowledge due to the intricate gearbox mechanics.

Chain Drive

Usage: Generally found in specialty or mountain electric tricycles, and possibly in custom-designed specialty tricycles, but rarely in conventional cargo electric tricycles.

Pros:

- Efficient Power Transfer: Can efficiently transmit power from the motor to the wheels.

- Applicability: Can be applicable in customized designs for specific use-cases where chain drive may be preferred.

Cons:

- Maintenance: Requires consistent maintenance, such as lubrication, to ensure smooth operation.

- Noise: May generate more noise compared to other drive types.

Shaft Drive

Usage: Although not commonly utilized in the electric cargo tricycle market, shaft drive systems are more frequently found in motorcycle tricycle.

Pros:

- Low Maintenance: Typically requires less regular attention compared to other systems.

- Durability: Tends to have a robust and durable construction.

Cons:

- Rarity: Not commonly adopted in the mainstream cargo tricycle industry, making it a less standardized option.

- Cost: Can be more expensive to implement and repair due to its intricate mechanism.

Why Gear Drives Dominate in Cargo Electric Tricycles?

Optimal Power Utilization: Ensures precise and efficient use of motor power for cargo transportation.

Located in Rear Axle: Centralized power distribution for balanced and stable drives, even with heavy loads.

Low Maintenance: Minimal care needed due to its internal location and durable design.

Reliable Performance: Offers steadfast and consistent operation across various terrains and load sizes.

Cost-Effective: Ensuring durable operation and minimizing operational costs, such as repair and upkeep.

Choice of Rear Axle

The rear axle is central to a tricycle cargo truck’s performance. It bears the load, ensuring stable and smooth rides across different terrains. Opt for a quality rear axle to boost your tricycle cargo truck’s reliability and efficiency in cargo transportation. Your choice matters, making every journey efficient and secure.

Protection Functions: The rear axle in a tricycle cargo truck is essential for balance and stability

Integrated Rear Axle (with Differential)

- Advantages:

More compact and simple to install.Potentially more reliable due to fewer connecting parts.Greater load-bearing capacity, especially suitable for trikes that need to carry heavy loads.

- Disadvantages:

If any part (like the differential) needs to be replaced or repaired, the entire axle unit might need to be replaced or repaired.

Slightly more expensive than the segmented rear axle.

Segmented Rear Axle (with Differential)

- Advantages:

Better maintainability. Convenient to dismantle using screws, allowing for only damaged parts to be replaced rather than the entire system.

Generally less expensive.

- Disadvantages:

Lower load-bearing capacity.

May require more maintenance due to its multiple-component design.

We cater to diverse market needs. For instance, for markets with heavy load demands and higher stability requirements, the integrated rear axle would be a better choice. Meanwhile, for budget-constrained markets that prioritize ease of maintenance, the segmented rear axle might be more appealing.

key Parameters of the Rear Axle:

The gearbox, centrally situated within the rear axle, not only connects the two wheels via half-shafts but also forms a crucial link to the motor.Serving as a crucial drive and transmission device.

Inside the gearbox lies an integral component – the differential.It aids in the rotation of the two rear wheels of the electric three-wheeler cargo loader, ensuring each wheel can move at different speeds. This is particularly helpful when the electric cargo tricycle is turning.

The differential gear ratio determines how power is transferred from the motor to the wheels of the electric tricycle, thereby affecting the vehicle’s starting force, maximum speed, and power efficiency.

The differential is not only the core part of the rear axle but also a key determinant in the performance of the electric three-wheeler loader.

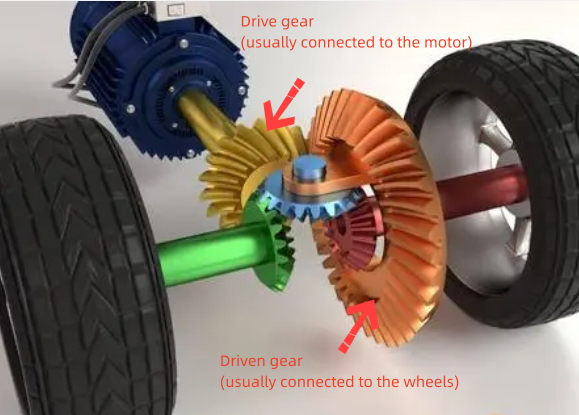

Gear Ratio:

Inside the differential (as shown in the picture): the ratio of the number of teeth between the drive gear (typically connected to the motor) and the driven gear (typically connected to the wheels).

For example:

- 3:1 gear ratio means the drive gear (motor) must rotate 3 times for the driven gear (wheel) to rotate once. (Faster speed but lower load capacity)

- 5:1 gear ratio means the drive gear (motor) must rotate 5 times for the driven gear (wheel) to rotate once. (Slower speed but greater force)

Two electric tricycles with the same motor parameters have different differential ratios: one is 31:10, and the other is 35:14. The latter is at least 10 km/h faster than the former, but has much lower hauling capacity.

To determine if an electric tricycle is power-oriented or speed-oriented based on the differential ratio, A smaller ratios indicates a speed-type tricycle, while a larger number indicates a power-type tricycle.

Standard Gearbox vs. Variable Speed Gearbox:

Utilizing a Variable speed gearbox(high-low speed differential). The integration of a gear-adjusting fork allows direct switching between high and low-speed gears, providing a seamless transition from optimizing speed on flat terrains to exerting additional power and torque when conquering hills or moving hefty loads. This mechanism ensures a versatile and efficient driving experience in varying conditions, demonstrated visually in the accompanying image.

Applicable Scenarios:

- High-Speed Setting: Primarily used in flat terrains and regular road conditions where minimal resistance is met, ensuring the tricycle navigates with optimized speed while ensuring fuel (or battery) efficiency.

- Low-Speed Setting: Aptly used in challenging conditions like steep inclines or when transporting hefty loads, where the tricycle requires additional torque and power to maintain stability and momentum without overburdening the motor.

Hill-Climbing Mode (Optional):

With our variable-speed gearbox, also known as the high-low speed transmission, riders benefit from a dedicated mechanical shift lever. This feature allows for easy switching to low speed during uphill climbs and high speed on smoother terrains. Essentially, this is our hill-climbing function, tailored to meet individual riding requirements and customizable based on specific needs.

Other Considerations in Gearbox for Optimal Durability and Power

The wall thickness of the gearbox casing, the material utilized, and the manufacturing process of the gears themselves are all pivotal elements. Moreover, the modulus of the gears is crucial, as it can directly impact the power transmission and durability of the entire vehicle.

At our facility, we meticulously engineer our gearboxes, ensuring each aspect is optimized to provide powerful, reliable, and long-lasting performance in all of our electric tricycles. This dedicated approach guarantees that power is transferred efficiently and reliably from the motor to the wheels, safeguarding both the performance integrity and the longevity of your vehicle!

Battery Selection for Electric Tricycles

Choosing the appropriate battery is crucial for electric tricycles. This not only directly determines the vehicle’s endurance, power, and charging time, but also affects the overall experience of the driver. Below is a detailed discussion about battery selection.

Lithium-ion vs. Lead-Acid: A Comparison

| Parameter/Voltage | Lithium-ion Battery | Lead Acid Battery |

|---|---|---|

| Purchase Price | Higher initial investment cost | Generally more affordable but might require more frequent replacements |

| Safety and Stability | Can be more volatile under conditions like overcharging but usually comes with advanced Battery Management Systems (BMS) for protection | More stable |

| Weight | Lighter and more energy-dense, making them suitable for portable applications | Compared to lithium batteries of the same capacity, it has a larger volume and is heavier |

| Lifespan | Generally offers longer lifespan with a higher number of charge-discharge cycles | Shorter lifespan and degrades faster after a certain number of cycles |

| Charging Speed | Faster charging capabilities | Slower charging times |

| Range and Performance in Cold Conditions | Retains a decent performance in cold temperatures, but range can be slightly diminished | More susceptible to performance drops in colder climates, resulting in reduced range |

Both lead-acid and lithium batteries are commonly used in leisure trikes. Your choice can be based on your budget

Battery Capacity Choose

| Parameter/Voltage | 48V | 60V | 72V |

|---|---|---|---|

| Battery Quantity | 4 batteries | 5 batteries | 6 batteries |

| Common Capacity | 20Ah, 32Ah | 32Ah, 45Ah, 52Ah, 58Ah | 45Ah, 52Ah, 58Ah,60ah |

| Recommend Motor Power | Below 600W | 800W-1500W | Above 2000W |

| Applicable Scenarios | Small power, smaller size, single row of seats, suitable for pure commuting | Medium power, double row of seats, suitable for passenger or cargo transport in flat areas, with good endurance | Large size, high power output, suitable for heavy load and dealing with sloping road sections |

| Vehicle Features | Canopy-free leisure electric tricycle, small flatbed tricycle for cargo transportation | Leisure tricycles, electric tricycle with canopy, cargo electric tricycle | Heavy load electric tricycles, semi-enclosed electric tricycles, electric tricycles with more than 4 seats |

| Cruising Range | 45-90 kilometers | 45-120 kilometers | 60-120 kilometers |

The 60V electric tricycle performs exceptionally in terms of cost-effectiveness. Not only does it come with comprehensive features and configurations, but it also offers a wide array of choices. When purchasing a tricycle, you can flexibly choose a suitable battery capacity and model based on your needs.

Other Key Parameters about Batteries

- Brand: Well-known brands represent reliability and high quality. They undergo strict quality checks and market validation.

- Manufacture Date: Batteries manufactured recently have better durability and stability.

- Safety: Ensure the battery has sufficient protection features, such as overcharging, over-discharging, and short circuit protection.

- Battery Position and Weight: These affect the balance of the vehicle. To ensure stability and safety, the selected battery should match well with the vehicle design.

When choosing a battery, one should not blindly pursue higher voltage and capacity. AGL will assist you in selecting the appropriate battery configuration based on the actual usage conditions in your electric tricycle’s target market. By matching the right motor power and usage requirements, we ensure not only the optimal performance of the tricycle but also that your investment is worthwhile, yielding a higher cost-performance ratio.

Suspension System for Electric Tricycles

Classification of Front Suspension System

Fork Shock Absorber

It is the primary choice for front suspension shock absorption in tricycles, especially those used for hauling goods or agricultural tasks. This design is simple, durable, and relatively low-cost.

Material: Typically made from steel or aluminum alloy.

3 types: Spring shock-absorbing front fork, hydraulic damper front fork, or a combination of spring and hydraulic damper front fork.

Work with us, and we will help you choose the right front fork based on the actual situation of your market, including the following details:

Material Quality: Opt for front forks made from high-quality materials, such as high-strength steel or aluminum. This ensures the durability and load-bearing capacity of the front fork.

Design and Construction: Choose front forks with reinforced structural designs, like thickened fork arms or enhanced welding points, to minimize the risk of bending and deformation.

Travel and Compression: Consider a larger travel – the measurement of the distance between compression and extension of the shock absorber. A larger travel can better absorb abrupt changes in terrain.

Damping Capabilities: A good hydraulic damping system can better control the movement of the front fork in complex terrains, providing a smooth riding experience.

Adjustability: Adjustable front forks allow for fine-tuning based on load and terrain, such as spring preload, compression, and rebound speed.

Compatibility with the Vehicle: Ensure the front fork is compatible with other parts of the tricycle, especially the tire size and braking system.

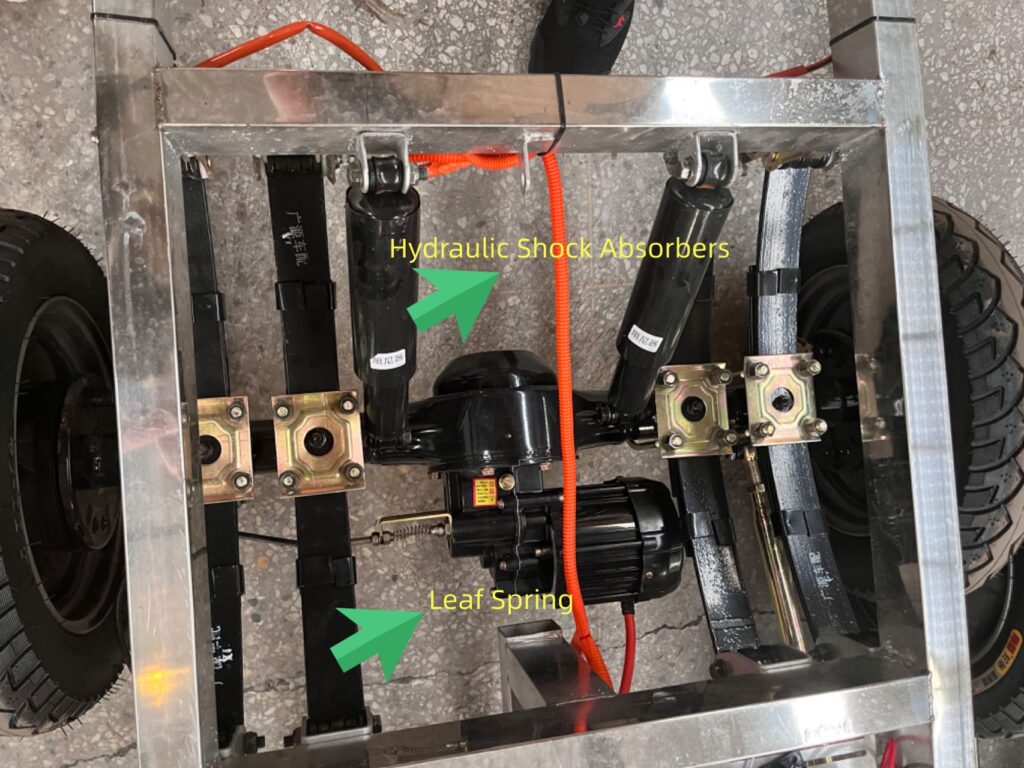

Classification of Rear Suspension System

The rear suspension system plays a crucial role in ensuring stable, smooth, and safe driving, especially when loading and unloading goods or traversing uneven terrain. Below are the key components and considerations

Leaf Spring

- Durability and Stability: The leaf spring structure is simple, stable, and durable, especially suitable for heavy loads and long-term use, hence it is commonly used in freight tricycles. It consists of multiple steel strips that can bend and disperse loads over a large range.

- Key Parameters: The number, thickness, and material quality of the leaf springs. More or thicker leaf springs typically mean the suspension can bear heavier loads.

- Maintenance: Leaf springs require minimal maintenance and the maintenance cost is relatively low.

- This is also the most commonly used rear suspension method for electric tricycle cargo truck at. present

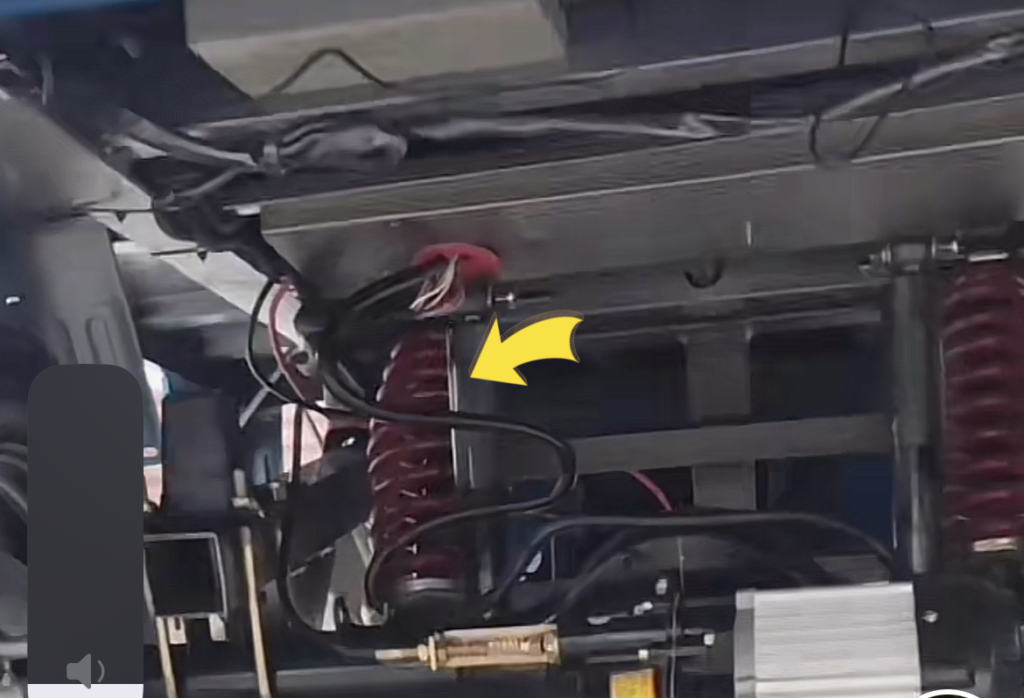

Coil Spring

- Use: Utilizes coil springs to absorb impacts.

- Comparison with Leaf Spring: Provides a softer and more comfortable riding experience compared to leaf springs, but may not be as durable under heavy loads.

- Key Parameters:

- Spring Rate: (A high spring rate means the spring is stiff, and it takes a greater force to compress the spring, while a low spring rate means the spring is softer.)

- Material: (The material of the spring affects its performance, durability, and weight.)

- Diameter: (Affects its performance and load-bearing capacity. Larger diameter springs may be able to bear larger loads, but they may also be heavier and take up more space.)

Hydraulic/Pneumatic Shock Absorbers

Function: Utilizes fluid or air resistance to control the movement of springs and suspension.

- Key Parameters:

- Damping Rate: High damping rate may be necessary for high-performance or heavy-load vehicles to provide better stability and control. Low damping provides a softer ride feeling, which is more suitable for general daily driving to increase comfort.

- Adjustable Settings: Allow users to adjust the performance of the shock absorbers based on different driving needs or conditions.

- Material Structure: In the suspension systems of electric tricycles and many other light to medium vehicles, the most commonly used shock absorber material is steel.

- Often paired with other types of suspension to suppress oscillation. Commonly paired with leaf spring suspension.

In partnering with us for your electric tricycle needs, you are ensured of a top-quality suspension system that promises durability, safety, and superior riding comfort. Entrust your needs with us, and experience the unparalleled service and expertise that set us apart in the electric tricycle industry.

Frame & Structure of Electric Tircycles

Material Selection for Electric Cargo Tricycles

Stainless Steel(202)

Surface Treatment: Corrosion-resistant, thus no treatment needed.(Ideal for transporting moist or corrosive items)

Advantages:

Adaptability in Coastal and Humid Areas: Due to its corrosion resistance, stainless steel is especially suitable for humid or coastal areas where salt air can accelerate rusting.

Aesthetic: Stainless steel has a natural luster, catering to market demands for a high-quality and upscale appearance.

Minimal Maintenance: Stainless steel is more wear-resistant and typically requires less maintenance than regular steel.

Wet Goods Hygiene: Stainless steel electric cargo tricycle, being pore-free, is ideal for transporting moisture-rich items like seafood. It can resist lingering odors, ensuring hygiene, making it perfect for seafood suppliers.

Disadvantages:

Cost: Due to the use of alloy elements and processing methods, stainless steel is generally more expensive than regular steel.

Potential for Surface Scratches: Although durable, stainless steel is prone to noticeable surface scratches, especially on polished surfaces.

Steel

Surface Treatment: Baked Paint, durable.(General rust and wear protection; General rust and anti-wear protection)

Advantages:

Strength: Steel is renowned for its excellent strength and rigidity, making it the preferred choice for frameworks that need to bear heavy loads.

Cost-Effectiveness: Generally, the price of steel is lower than many other materials, making it the go-to option for those seeking a balance between cost and performance.

Durability: Steel frames are sturdy and durable, able to withstand harsh environments without serious wear and tear.

Repairability: If damaged, steel frames can typically be repaired.

Disadvantages:

Weight: Steel is often heavier than materials like aluminum, which can affect the overall efficiency and agility of the vehicle.

Corrosion: Steel is prone to rust, especially when the protective layer or paint is damaged.

Material Thickness of Electric Tricycles

Material thickness directly affects the durability and performance of the tricycle, and customization can achieve the best match with specific operational requirements.

Electirc Tricycle Bottom Plate Thickness

- Conventional Range: 1 mm to 1.5 mm.

- Purpose: To ensure optimal weight and strength for goods transportation.

- Customized Thickness: Adjust the thickness according to the type of goods and frequency of use.

Electirc Tricycle Chassis Crossbeam (Side Beams and Main Beams)

- Conventional Range: 2 mm to 3 mm.

- Purpose: To provide structural integrity, especially under heavy loads.

- Customized Thickness: Modify according to anticipated load and type of terrain.

Cargo Box Dimensions

Standard Sizes:

- Small: 1.1 meters x 0.85 meters: Suitable for lightweight goods and quick city commuting.

- Medium: 1.3 meters x 0.95 meters; 1.5 meters x 1.0 meter: Offers a balance of capacity and flexibility, suitable for various purposes.

- Large: 1.6 meters x 1.1 meters; 1.8 meters x 1.2 meters: Specifically designed for transporting larger or heavier goods.

If you have special size requirements, AGL Trike can meet them all.

Other key Parameters

Welding Quality: Uniform weld seams and spots, no burn-through or cracks, appropriate penetration, and professional workmanship.

Connection Components: Use of high-quality bolts, nuts, and hinges. Components are securely fastened with no looseness or rattling parts.

Protective Edges: Generally in the form of rubber or metal guards, the protective edges on corners and exposed edges are smooth and well-fitted. They are wear-resistant and the materials used are durable.

Brake System Guide of Electric tricycles

Selection of Brake Types

Drum Brakes

Features:

Cost-Effective: Drum brakes generally have lower manufacturing and maintenance costs.

Braking Force: Due to their specific design, they provide greater braking force in some applications.

Applicable Scenarios: Drum brakes are typically used in vehicles with large loads, such as cargo tricycles, because they can provide the necessary braking force.

Disadvantages:

Not as good at heat dissipation as disc brakes, which can easily lead to brake overheating.

Response time may be slightly slower.

Disc Brakes

Features:

Heat Dissipation: Disc brakes have excellent heat dissipation performance, allowing for rapid cooling and reducing the risk of brake overheating. While the initial cost might be higher, the long-term maintenance cost of disc brakes may be lower.

Responsiveness: Provide instant and even braking force.

Applicable Scenarios: Due to their heat dissipation and responsiveness advantages, disc brakes are often used in vehicles that require rapid braking and high performance.

Disadvantages:

Initial installation cost may be higher.

Might require more frequent maintenance.

Hydraulic Brakes

Features:

Sensitivity: Hydraulic brakes use a hydraulic system to transmit braking force, providing high sensitivity and immediate response.

Torque: Hydraulic brakes can provide consistent braking force without torque loss.

Applicable Scenarios: For high-performance vehicles that require precise braking and immediate response, such as electric tricycles or sports tricycles, hydraulic brakes are the ideal choice.

Disadvantages:

If the hydraulic system fails, it may lead to brake failure.

Need to regularly check and maintain the hydraulic fluid level. (This is the most expensive type)

Application and Standard Matching of Brakes

In the present electric three-wheeler loader market, drum brakes are a common configuration for the following reasons:

Cost-Effective: When compared to other braking systems, drum brakes have a lower manufacturing cost. This is a significant attraction for both producers and consumers, especially in the electric three-wheeler loader market where high cost-performance ratios are sought after.

Durable and Low Maintenance: Drum brakes, with their simple structure and long lifespan, mean that electric three-wheeler loader owners can save more on maintenance and replacement costs, ensuring the continuous and stable operation of the vehicle.

Adaptable: The design of drum brakes is excellent for handling a larger braking torque, making them especially suitable for electric three-wheeler loaders carrying heavy loads.

Beyond the sole drum brake configuration, some electric three-wheeler loaders select a combination of front wheel disc brakes and rear wheel drum brakes for the following reasons:

Front Wheel Disc Brakes: Disc brakes offer a rapid and clear braking response, vital for front wheels. During emergency braking, the vehicle’s center of gravity will tilt forward, requiring the front wheels to have faster and stronger braking forces.

Rear Wheel Drum Brakes: Drum brakes excel in continuous braking and stability, especially when carrying heavy goods, making them the ideal choice for the rear wheels of electric three-wheeler loaders.

Cost Consideration:Because disc brakes are more expensive and drum brakes are cheaper, a combination of front disc and rear drum brakes can ensure effective vehicle braking while also reducing costs. a front and rear double disc brake setup is beneficial for achieving high-frequency action and ensuring vehicle control.

Choose ALG Trike, one of the leading electric trike manufacturers, can ensure not only safe and stable braking but also accommodate various driving and loading demands.

Tire and Wheel Hub Essentials

Tire selection for a 3-wheeler electric cargo truck

Tire Size: For example, if the tire parameter is “3.0-12”, where “3.0” represents the tire width, and “12” indicates the inner diameter of the tire. Generally, larger sizes are more expensive. For instance, a 3.0-12 tire will be pricier than a 3.0-8 tire.

Tire Material: Mainly, there are two types: Radial tire and Bias tire.Radial tire due to their strength, exhibit superior durability, especially under heavy load and long-distance driving. If comfort riding is the preference, Bias tire would be sufficient.

Tire Ply Rating: Common specifications include 4PR, 6PR, 8PR. These ratings represent the tire’s load-bearing capacity. The more the ply number, the stronger its load-bearing capacity will be.

Tire Shape: Tires mainly come in two shapes: flat-top and arched. Flat-top tires are thicker and more wear-resistant, suitable for bearing larger loads; whereas arched tires provide a more stable riding experience. Therefore, some three-wheelers might opt for arched tires in the front and flat-top tires in the rear.

Wheel Hub Material

Aluminum Alloy Wheel Hub: Aluminum alloy is popular for its lightweight, high strength, and good corrosion resistance. It can provide better heat dissipation, helping to reduce brake overheating, and offer a certain degree of weight reduction for the vehicle.

Steel Wheel Hub: Steel is a heavier but very sturdy and durable material. This type of wheel hub typically costs less, but its heavier weight may slightly sacrifice some performance.

Tires are the only point of contact between the electric tricycle and the ground, making the choice of suitable tires crucial. For smooth roads, we recommend choosing tires with low rolling resistance and a softer composition, offering better comfort and energy efficiency. On rugged or muddy terrains, tires with deep treads should be selected to ensure good traction.

Transport Packaging at AGL-Trike

Vehicle Delivery Packaging

At AGL-Trike, we pride ourselves on our attention to detail and our commitment to the highest quality in every aspect, right down to our packaging. To provide our clients with a visual understanding of our professionalism, we showcase several standard full-vehicle delivery packaging methods. Our approach ensures the utmost safety and protection for the product, ensuring it reaches you in pristine condition.

Basic Standard Sponge Packaging

Wooden Frame Packaging

Metal Frame Packaging

- Metal Frame with Wooden Crate Packaging

More Custom Packaging Options

Understanding that each client might have specific needs and preferences when it comes to transporting and assembly, we offer a range of packaging choices:

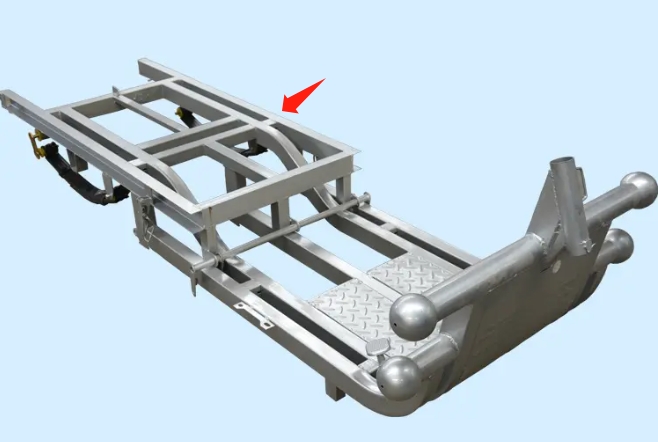

SKD (Semi Knocked Down): This packaging method involves partial assembly. Major components are packed separately, offering a balance between ease of transportation and reduced assembly effort at the destination.

CBU (Completely Built Up): The vehicle is fully assembled and ready for immediate use upon arrival. This method is ideal for clients who prefer a plug-and-play solution without the need for post-shipment assembly.

CKD (Completely Knocked Down): This involves a complete disassembly of the vehicle. Each component is securely packed individually, ensuring compactness and efficiency during transportation. This method is perfect for destinations with specific import regulations or for clients who have specialized assembly capabilities in-house.

By offering these diverse packaging options, we ensure that our clients can select a method that aligns perfectly with their logistics, assembly capabilities, and preferences. Our goal at AGL-Trike is to make every aspect of your purchase, including transportation and packaging, as seamless and tailored as possible.

FAQs on Wholesale and Customization of Cargo Electric Tricycles

What are the MOQ of the Order?

For optimal shipping cost, we advise filling a 20GP container. However, orders not filling a container are accepted with a note of higher shipping costs. Mix 1-2 different tricycle styles in a single container for variety and cost efficiency.

Ensure you get the best in shipping, cost, and variety with our flexible MOQ and shipping options.

What is the expected delivery time?

For standard models, expect a delivery time of 15-25 days. For special custom orders, delivery times are estimated based on your specific requirements, ensuring you know when to expect your order, and can plan accordingly.

What is the warranty period for your electric cargo tricycles?

We offer a 1-year warranty for our electric cargo tricycles, covering any non-man-made damages. Rest assured that we stand behind the quality and durability of our products, providing you with reliable post-purchase support.

Do you ship internationally?

Yes, we ship our cargo electric tricycles worldwide with trusted logistics partners.

Are your cargo electric tricycles certified and compliant with international standards?

Absolutely, our tricycles adhere to international safety and quality standards, ensuring reliability and safety for all our customers.

How is the after-sales service?

We provide comprehensive after-sales service including spare parts supply, technical support, and other assistance to ensure the smooth operation of your cargo electric tricycle.

Kickstart Your Project Now!

Got a project in mind or a question to ask?

Don’t wait! Our team is ready to help.

We’re committed to responding within 12 hours.

- +86 18367809612(Whatsapp)

- info@agl-trike.com

We will contact you within 12 hours, please pay attention to the email with the suffix “@agl-trike.com”.