You found a manufacturer with an amazing price, but something feels off. Choosing the wrong supplier could mean receiving poor-quality products, fake specifications, or even losing your entire investment.

The biggest mistake is chasing the lowest unit price without considering the manufacturer's experience, the product's suitability for your market, and the total landed cost. A cheap price often hides poor quality, fake specs, and a lack of export support, leading to much higher costs later.

At AGL-Trike, we often speak with buyers who come to us after a bad experience elsewhere. They learn the hard way that a 5-10% price difference on paper can mean a 100% loss in reality. The electric tricycle industry is fairly transparent on pricing, so when a price seems too good to be true, it usually is. Finding a reliable partner is far more important than saving a few dollars on the unit. Let's break down the most common—and costly—mistakes we see new importers make.

Are You Choosing a Tricycle Without Matching It to Your Market Needs?

You saw an electric tuk-tuk that is a bestseller in Asia. You assume it will be a hit in your country, so you place a large order without doing any local research.

A huge mistake is buying a "popular" model without confirming it solves a local problem. Your market's roads, regulations, weather, and customer needs—not another country's trends—must determine the right vehicle, whether it's for cargo, passengers, or farming.

A good manufacturer doesn't just sell you a product; they act as a partner. When a new client contacts us, one of the first things we ask is, "Tell me about your market. Are there a lot of hills? What is the main job for the tricycle?" We know that selling you a trike that fails or doesn't sell is bad for both of us. An inexperienced supplier will just take your order for any model, no questions asked, because they don't know the difference. You must be the expert on your market. Don't assume a vehicle designed for the flat, paved streets of one city will work on the unpaved, hilly roads in your rural region. You need to match the product to the local terrain, the typical load capacity required, and what your end-users can afford.

Do You Understand the Electric Tricycle Configuration Options Before Ordering?

You're trying to lower the cost, so you select the cheapest motor and battery options. The supplier agrees without any questions, and you feel like you got a great deal.

Failing to understand what key components do is a recipe for disaster. Cheaper parts directly lead to poor performance, short lifespan, and unhappy customers. An untrustworthy supplier will gladly let you choose undersized parts to win the order.

This is where "cheap" becomes dangerous. Let me share a real story. We had a new client from Mauritius who came to us after being burned by another supplier. He had ordered trikes with a "1000W" motor. But when the vehicles struggled with small loads, he investigated. The motor was physically the size of a 500W motor. He was sold a lie. The same supplier used low-grade tires that wore out in months and battery packs with recycled cells that died quickly. He saved 10% on the initial price but ended up with a container of useless machines.

Always remember:

- Motor & Controller: This is the heart of the trike. An undersized motor will overheat and fail when carrying heavy loads.

- Battery: The choice between lead-acid and lithium, and the battery's real capacity (Ah), determines the vehicle's daily range and lifetime. Fake capacity is a common trick.

- Frame & Materials: A cheaper price often means thinner steel and poor welds, which can lead to frame cracks and rust.

- Tires & Brakes: These are critical for safety. Low-quality tires wear out fast, and weak brakes are a serious hazard.

Are You Verifying the Manufacturer’s Export Experience and Certifications?

The manufacturer's website looks professional, and they communicate well in English. You assume they are experienced exporters and place your order without further checks.

Many Chinese factories only sell domestically; they have no idea how to properly pack a container, handle customs documents, or comply with international shipping rules. You must verify their export license, past shipping records, and relevant certifications (e.g., CE, ISO).

A factory that can't prove its export experience is a huge red flag. Exporting is complex. It involves specific packing methods to prevent damage, accurate paperwork (like the Bill of Lading and Packing List) for customs, and ensuring the product complies with your country's regulations. An inexperienced factory can cause massive delays at the port, leading to storage fees or even having your shipment rejected. Before you send any money, ask for proof. Request photos of them loading containers for other clients. Ask for their export certifications. Even better, schedule a live video call for a factory tour. With modern technology, there is no excuse for not seeing the facility and asking questions in real-time. This simple step can save you from a massive headache.

Do You Know the Total Landed Cost — Not Just the Unit Price?

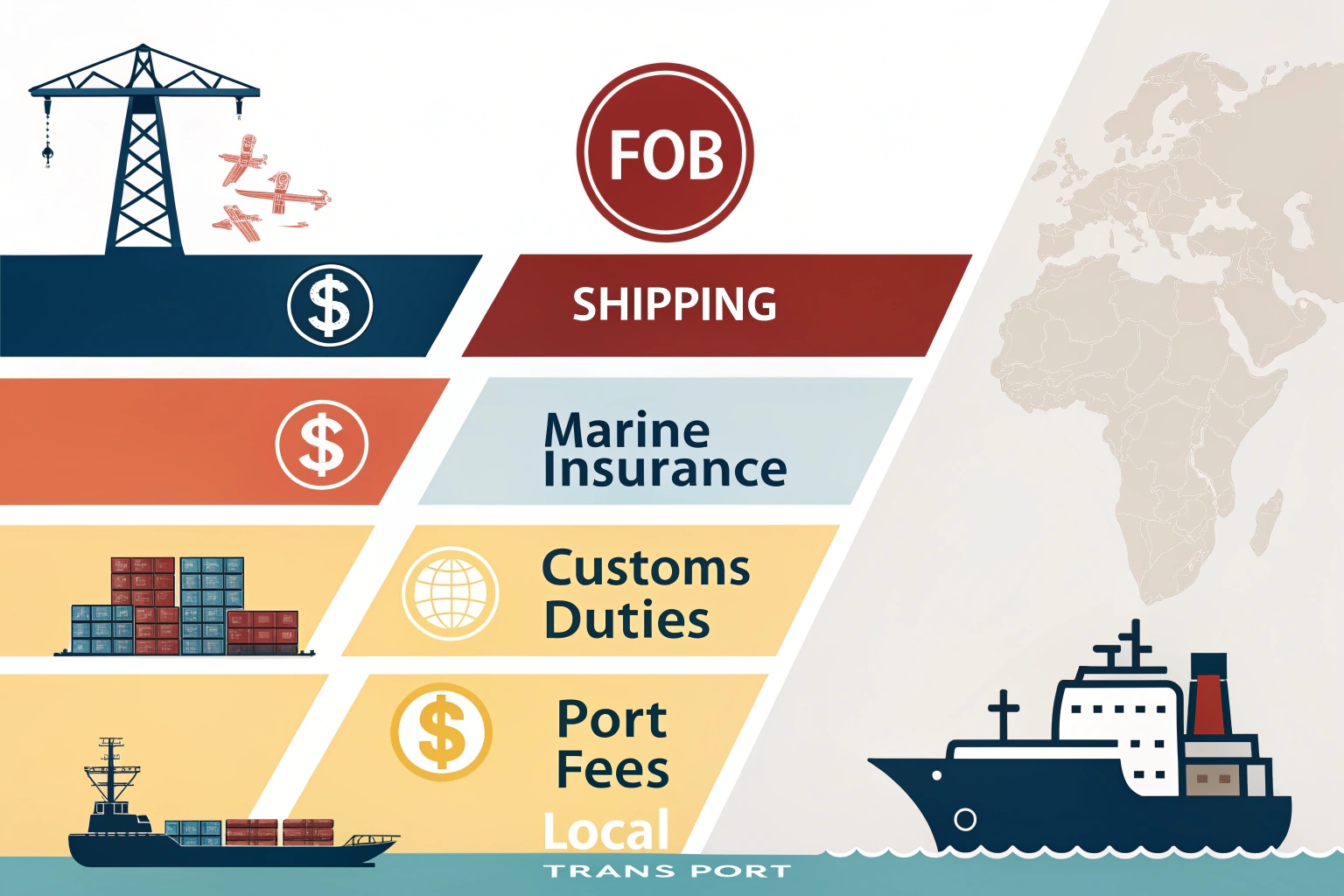

You get an FOB (Free On Board) price of $1,000 per unit from the factory. You multiply it by the number of units and assume that's your total cost for the inventory.

The FOB unit price is just the beginning of your expenses. The biggest financial mistake is not calculating the Total Landed Cost, which includes shipping, marine insurance, customs duties, port fees, and local transport. This can add 30-50% or more to your total cost.

New importers get excited by a low factory price and forget about the long journey the product takes to get to their warehouse. An experienced manufacturer can help you with this. We can provide you with the exact CBM (cubic meters) and weight for your order, which your freight forwarder needs to give you an accurate shipping quote. We can also provide the correct HS Code to help you estimate your customs duties. An unprofessional supplier will give you vague estimates or incorrect data, leaving you with surprise bills that destroy your profit margin. Before you commit to an order, you must have a clear estimate for every single cost involved in getting the product from the factory floor to your front door. The small 5% you "saved" on the FOB price can easily disappear with one unexpected shipping charge.

Conclusion

Choosing a manufacturer is a partnership. Prioritize trust, proven experience, and a product that truly fits your market over a deceptively low price, and you will build a successful, long-term business.