¿Planeando su primer pedido a granel? ¿No estás seguro de cuántas unidades comprar para llenar un contenedor y mantener bajos los costos de envío? Vamos a obtener los números que necesita para planificar su estrategia de adquisición.

Un contenedor de 20 pies puede contener 15-25 triciclos de carga pero solo 3-4 modelos de pasajeros adjuntos. El número exacto depende en gran medida del tipo de triciclo y si se envía ensamblado (CBU) o en partes (SKD/ERC), lo que ahorra drásticamente espacio.

Esta es una de las primeras preguntas que me hace cada nuevo distribuidor o gerente de proyectos gubernamentales. Tu objetivo es bajar el "Costo de aterrizaje" para cada triciclo eléctricoy maximizar el espacio de su contenedor es la mejor manera de hacerlo. La respuesta no es un solo número, porque no todos los triciclos electrónicos son iguales. Un triciclo de carga abierto que podemos desarmar es muy diferente de un modelo de pasajeros completamente cerrado con una carcasa sólida. Vamos a desglosar para que pueda planificar su pedido con confianza.

¿Cuántos triciclos eléctricos puede contener un recipiente de 20 pies?

¿Planea comenzar con un contenedor más pequeño de 20 pies? ¿Le preocupa ordenar muy pocos y desperdiciar costos de flete? Veamos los números de carga reales para diferentes modelos.

Un contenedor estándar de 20 pies puede ajustarse a un alto volumen de modelos de diseño abierto como triciclos de carga eléctricos (15-25 unidades), pero muy pocos modelos completamente encerrados (3-4 unidades) debido a su forma fija y voluminosa.

Un contenedor de 20 pies es el punto de partida más común para los nuevos importadores que prueban su mercado. La clave para que sea rentable es comprender cómo el tipo de triciclo eléctrico que elija afecta la cantidad de carga. La diferencia puede ser enorme.

La razón de esta variación es nuestro método de embalaje. Para modelos como el triciclo de carga eléctrica o triciclo de ocio, los enviamos skd (semi derribado). Quitamos las ruedas, el manillar y el dumen de carga, luego apilamos los marcos y las piezas de manera eficiente. Para un taxi eléctrico tuk-tuk, podemos separar el techo del chasis. Esto nos permite empacarlos con fuerza.

Sin embargo, un triciclo de pasajeros eléctricos cerrados tiene un cuerpo moldeado de una pieza. No podemos desmontarlo sin requerir que haga soldadura y pintura compleja. Se envía casi completamente ensamblado (CBU), por lo que ocupa mucho espacio. Esto es lo que generalmente puede esperar para un contenedor de 20 pies:

| Modelo de triciclo eléctrico | Unidades promedio en un contenedor de 20 pies | Método de embalaje |

|---|---|---|

| Triciclo de carga eléctrico | 15 - 25 unidades | SKD / ERC |

| Triciclo eléctrico de ocio | 15 - 25 unidades | SKD / ERC |

| Electric Tuk Tuk (taxi) | 10 - 18 unidades | Skd |

| Triciclo de basura eléctrico | 3 - 10 unidades | CBU o SKD |

| Triciclo de pasajeros cerrados | 3 - 4 unidades | CBU |

¿Cuántos triciclos eléctricos puede contener un contenedor de 40 pies o 40HQ?

¿Listo para ampliar su operación con un pedido más grande? ¿Se pregunta si un contenedor de cubos de 40 pies de altura vale el costo adicional? Exploremos la capacidad de los contenedores más grandes.

Un contenedor de 40 pies generalmente contiene más del doble de la cantidad de un contenedor de 20 pies. Un 40HQ (alto cubo) proporciona espacio vertical adicional, a menudo permitiendo una capacidad adicional del 10-15%, que es ideal para pedidos a granel.

Para distribuidores establecidos y licitaciones gubernamentales, un contenedor de 40 pies es el estándar para lograr el mejor costo de envío por unidad. Hay dos tipos: el GP estándar de 40 pies (propósito general) y la HQ de 40 pies (Cubo alto). El HQ es de aproximadamente un pie (30 cm) más alto, y esa altura extra hace una gran diferencia cuando estamos apilando marcos y cajas de carga. A menudo nos permite encajar en una capa adicional completa de piezas, maximizando su inversión de carga.

El tamaño de este contenedor realmente resalta los beneficios del envío SKD. Podemos colocar una gran cantidad de desmontados triciclos de carga eléctricos En el interior, generando el costo de flete por unidad. Para los modelos voluminosos de CBU, el aumento es menos dramático pero sigue siendo significativo. Los mayoristas y gerentes de flota que priorizan un costo bajo de tierra casi siempre optan por un contenedor de 40HQ.

Estas son las cantidades de carga típicas para un contenedor de 40 pies:

| Modelo de triciclo eléctrico | Unidades promedio en un contenedor de 40 pies/40HQ | Método de envío |

|---|---|---|

| Triciclo de carga eléctrico | 45 - 60 unidades | SKD / ERC |

| Triciclo eléctrico de ocio | 45 - 60 unidades | SKD / ERC |

| Electric Tuk Tuk (taxi) | 20 - 38 unidades | Skd |

| Triciclo de basura eléctrico | 6 - 30 unidades | CBU o SKD |

| Triciclo de pasajeros cerrados | 8 - 12 unidades | CBU |

¿Qué factores afectan cuántos triciclos se ajustan en un contenedor?

¿Obtener una cotización para 25 unidades, pero la fábrica dice que solo 22 encajan? Esto puede ser confuso. Aclaremos las variables clave que determinan la cantidad de carga final.

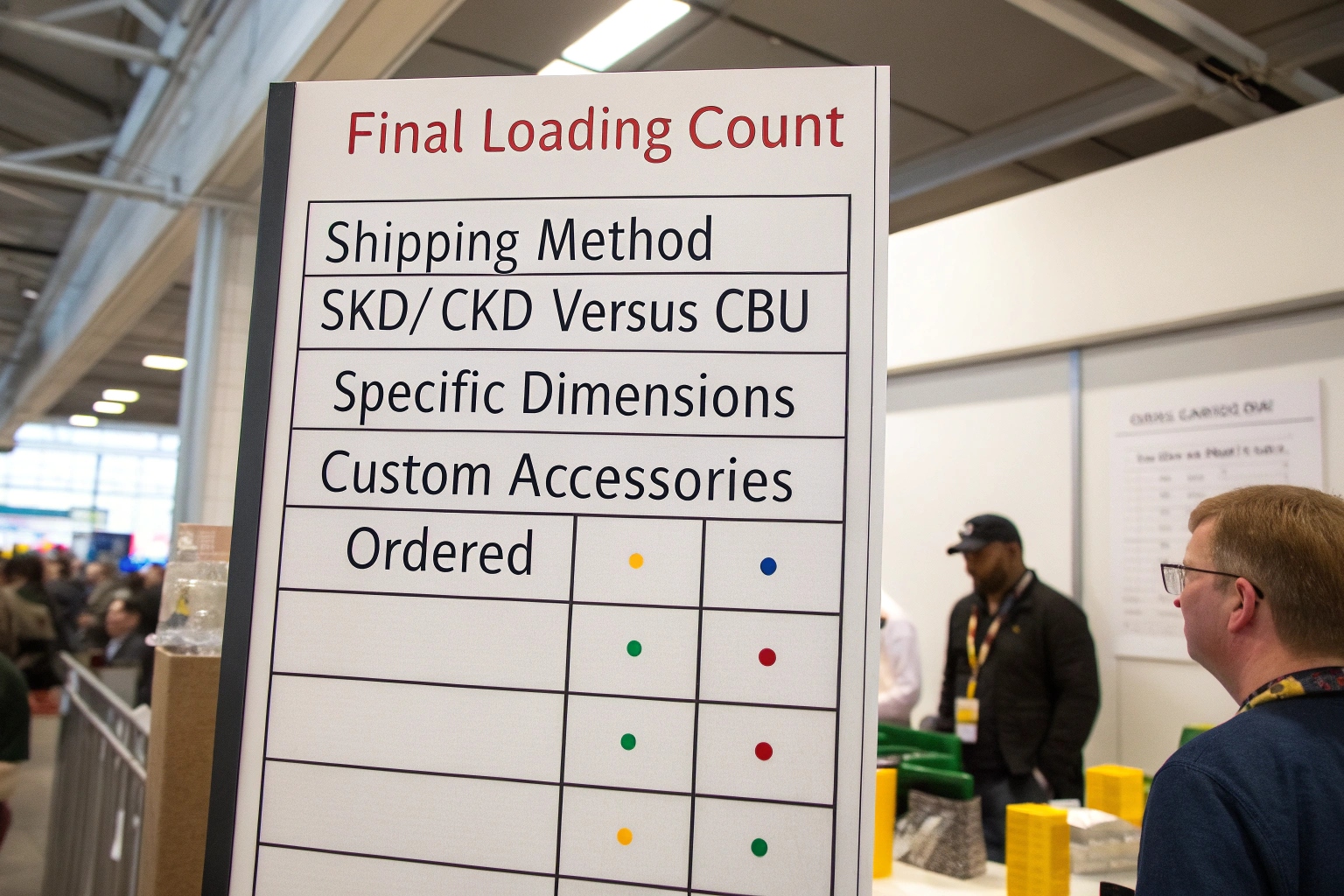

El recuento de carga final está determinado por tres factores principales: el método de envío (SKD/CKD vs. CBU), las dimensiones específicas del modelo y cualquier accesorio personalizado que haya ordenado.

Los números que proporcioné son estimaciones excelentes, pero el recuento final para su pedido específico puede cambiar. Como fábrica, calculamos esto precisamente antes de finalizar su factura proforma. Estos son los factores que consideramos:

1. Método de embalaje: SKD/CKD es el cambio de juego

Este es el factor más importante.

- SKD/CKD (semi/completamente derribado): Desmonamos el triciclo en módulos: marco, ruedas, caja de carga, ejes. Estas partes pueden ser anidadas y apiladas de manera eficiente. Este método es perfecto para triciclos de carga abiertos y tuk-, permitiéndonos ajustar muchas más unidades. Su equipo solo necesita hacer un ensamblaje relacionado con el atornillado a nivel local.

- CBU (Completamente Construido): Esto es para modelos que no se pueden desmontar fácilmente, como triciclos de pasajeros adjuntos con fibra de vidrio de una pieza o conchas de metal. Se envían casi todo, ocupando mucho espacio fijo. Intentar enviarlos como kits requeriría soldadura y pintura complejas al final, lo cual no es práctico.

2. Modelo de vehículos y dimensiones

No hay dos modelos exactamente iguales. Un triciclo de carga de alta resistencia con una cama de carga de 2 metros de largo ocupará más espacio que un modelo de ocio compacto. El amplio rango para triciclos de basura eléctrica (3-10 unidades en 20 pies) es un ejemplo perfecto. Se puede enviar un modelo con un contenedor de basura simple y extraíble SKD. Un modelo con un mecanismo de vertido hidráulico grande e integrado debe enviarse CBU y ocupar mucho más espacio.

3. Personalizaciones y accesorios

Cada modificación puede afectar el plan de embalaje. Si solicita neumáticos más grandes, un techo de longitud completa en un triciclo de carga o espejos especializados de visión lateral, estas piezas deben caber en el contenedor. A veces, estos pequeños cambios pueden evitar que se ajustemos a las últimas una o dos unidades. Siempre contabilizamos esto en nuestro plan de carga.

¿Cómo maximizar el espacio al cargar triciclos eléctricos?

¿Quiere obtener cada último dólar de valor de su costo de flete de contenedores? Debe trabajar con un proveedor que sabe cómo empacar de manera eficiente. Es una habilidad que hemos perfeccionado en miles de envíos.

Maximizamos el espacio del contenedor utilizando métodos de embalaje SKD expertos. Esto incluye el desmontaje estratégico, los marcos de anidación, el manillar invertido y el uso de cada pequeño espacio para empacar componentes como ruedas, cargadores y kits de herramientas.

Cargar un recipiente con piezas de triciclo eléctricas SKD es como un juego de Tetris de alto riesgo. Nuestros cargadores profesionales tienen un sistema para asegurarse de que no se desperdicie espacio. Así es como bajamos su costo por unidad y le pasamos los ahorros.

Estas son algunas de las técnicas que utilizamos:

- Desmontaje estratégico: No solo desmontamos las cosas al azar. Creamos módulos que son fáciles de volver a montar pero también fáciles para nosotros para apilar. Por ejemplo, todo el conjunto del eje trasero podría permanecer como una sola pieza.

- Anidación y apilamiento: Apilamos los marcos uno encima del otro, a menudo invertidos, con espuma protectora en el medio para evitar rasguños. Las cajas de carga se anidan entre sí, como tazones.

- Usando cada brecha: Los espacios vacíos dentro de los marcos apilados o las cajas de carga no se desperdician. Aquí es donde empacamos las ruedas, los faros, los cargadores y las bolsas de pernos.

- Secuencia de carga optimizada: Hay un orden específico para la carga. Los marcos pesados van en la parte inferior, con componentes más ligeros como defensas de plástico y techos apilados en la parte superior.

Este proceso cuidadoso es algo que solo se puede hacer correctamente en la fábrica. Es por eso que siempre recomendamos FCL (carga de contenedor completa) Envíos, ya que garantiza que este embalaje especializado se realice de manera segura y segura.

Conclusión

El número de triciclos eléctricos en un contenedor varía ampliamente según el modelo, pero el uso de empaque SKD/ERC con envíos FCL es la clave para maximizar el valor y reducir el costo de su aterrizaje.