You picked a powerful motor but paired it with a weak controller. Now your cargo rickshaw struggles on hills, overheats, and can’t handle heavy loads. This mismatch is costing you time, money, and damaging your equipment.

Match your controller by ensuring its voltage matches the battery and its current rating (in amps) is slightly higher than the motor's needs. Use this formula to estimate: Controller Amps ≈ Motor Watts ÷ Voltage ÷ 0.8. Give it a small buffer for performance.

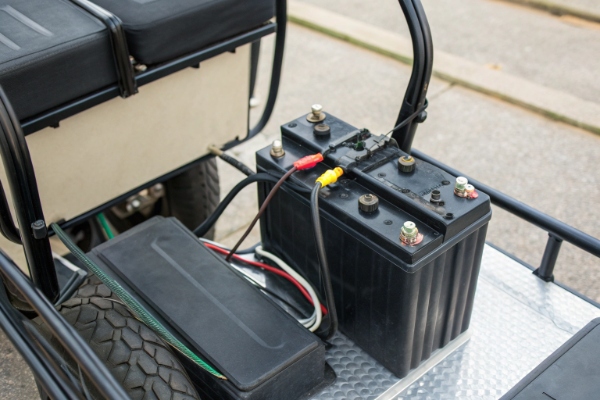

As a supplier, this is one of the most common technical questions I get. The controller is the "brain" of your e-rickshaw, telling the motor how much power to draw from the battery. Getting this pairing right is the key to unlocking reliable performance, especially for a hardworking cargo vehicle. It’s not just about matching numbers; it’s about understanding the entire power system. Let's dig deeper.

How do controller voltage and amps decide which motor is suitable?

It's easy to get lost in technical specs like "MOS tubes" and "wattage." But ignoring the basics of voltage and current is a recipe for disaster. This simple mistake can lead to poor performance, overheating, and even a completely burnt-out controller.

The controller's voltage must exactly match your battery's voltage. Its maximum current (amps) determines the motor power it can support. A controller with a higher amp rating can safely power a stronger motor for heavy loads and climbing hills.

Think of it like a water pipe. Voltage is the water pressure, and it has to be a perfect match. Amps are the pipe's diameter—a wider pipe allows more water (power) to flow. The number of MOS tubes inside the controller is a rough indicator of its amp capacity. More tubes generally mean it can handle more current and dissipate heat better.

Here is a simple rule I give my clients:

- Match Voltage First: If your battery is 60V, your controller must be 60V. No exceptions.

- Calculate Current Needs: Use the formula: Controller Amps ≈ Motor Watts ÷ Voltage ÷ 0.8. The "0.8" accounts for efficiency losses.

- Add a Buffer: Always choose a controller with a slightly higher amp rating than your calculation. This provides a safety margin, prevents overheating, and delivers better performance when you need it most, like starting with a heavy load.

For example, for a 1200W motor on a 60V battery:

- Amps ≈ 1200W ÷ 60V ÷ 0.8 = 25A.

- You should look for a controller with a rated current of around 30-35A.

What are the right controller options for different motor powers?

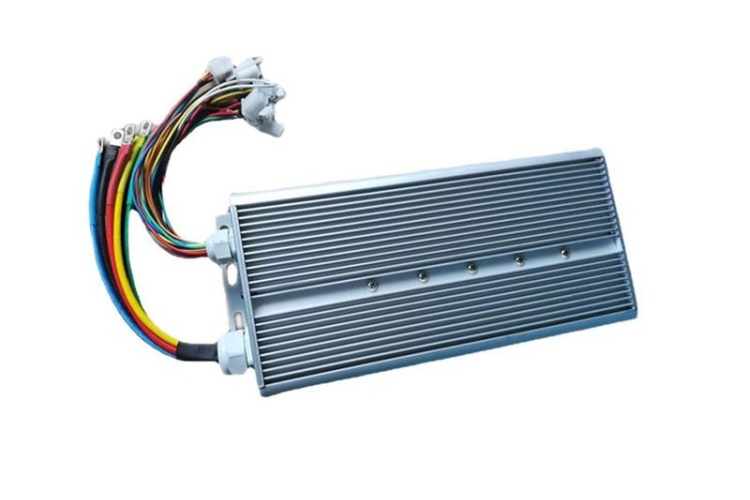

You need to buy a controller, but the options seem endless: 12-tube, 18-tube, 24-tube. Choosing the wrong one means you either pay too much for an oversized controller or get one that can't handle your cargo vehicle's demands.

The right controller is based on the motor's power range. A 12-15 tube controller is fine for an 800W motor, but a 1500W motor doing heavy work needs an 18-24 tube controller. For a 3000W motor, you must use a heavy-duty 36-tube model or higher.

Based on thousands of vehicles I've configured for clients, there are clear patterns for matching controllers to motors. The number of MOS tubes is a practical shorthand for current capacity. Here is a table that breaks down the most common pairings for cargo electric rickshaws.

Controller Matching Guide by Motor Power

| Motor Gücü | Ortak Kullanım Durumu | Recommended Controller (Tubes) | Typical Current Limit (Amps) |

|---|---|---|---|

| 800W | Light cargo, urban delivery on flat roads | 12-15 tubes | ~30-40A |

| 1200W | General-purpose cargo, moderate loads | 15-18 tubes | ~40-50A |

| 1500W | Heavy-duty cargo, frequent hill climbing | 18-24 tubes | ~50-60A |

| 3000W+ | Industrial use, very heavy loads, steep terrain | 24-36 tubes (or more) | 60A and above |

Always remember to check the controller's label for the official "Max Current (A)" rating. While tube count is a great guide, the amp rating is the number that truly matters. A slightly oversized controller is a good investment, as it runs cooler and lasts longer. എന്നാൽ, an excessively large controller can make the vehicle too aggressive on startup, which is hard on the battery.

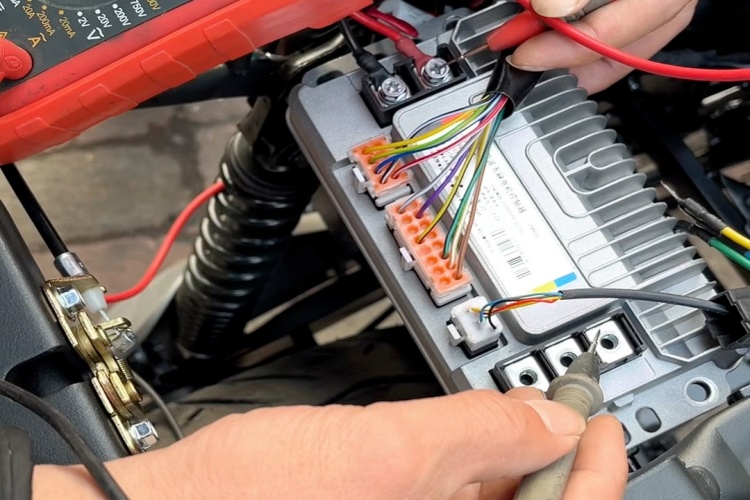

How do advanced controller features affect motor output?

You have a controller that matches your motor on paper, but the ride feels jerky or the top speed is disappointing. You're missing out on the performance gains that modern controller technology can offer.

Features like sine-wave control provide a smoother, quieter ride. Field-weakening (or "flux weakening") boosts top speed on flat ground. Speed limit functions give you control over vehicle safety and efficiency, directly impacting how the motor behaves.

Modern controllers do much more than just send power to the motor. They intelligently shape that power to improve the driving experience and performance. When I consult with clients building fleets, these are the features we discuss.

-

Sine-Wave vs. Square-Wave Control:

- Square-Wave: This is the older, cheaper technology. It’s effective but can be noisy and make the motor startup feel jerky. It's like flipping a power switch on and off.

- Sine-Wave: This is the modern standard for passenger and high-end cargo vehicles. It delivers power in a smooth, continuous wave. This results in a nearly silent motor, much smoother acceleration, and slightly better efficiency.

-

Field-Weakening (Flux Weakening):

This is essentially an "overdrive" gear for your motor. At high speeds, the controller intelligently manipulates the motor's magnetic field to let it spin faster than its normal rated speed. This feature is great for increasing the top speed on flat roads but doesn't help with climbing hills. -

Speed Limit Functions:

Many controllers come with multi-speed switches (e.g., a "1-2-3" button). This allows the operator to limit the top speed and acceleration. "Mode 1" might be an eco-mode for saving battery, while "Mode 3" provides maximum power for hills or heavy loads. This is a crucial feature for managing battery life throughout the day.

What should buyers check to ensure reliability for local road conditions?

You've matched the specs perfectly, but six months later, your controller fails in the middle of a rainy season or after a day on dusty roads. Technical specs are meaningless if the controller can't survive the real world.

Buyers must check the controller's physical construction. Look for a large, durable aluminum casing with deep cooling fins for heat dissipation. Ensure it has a good IP (Ingress Protection) rating for water and dust resistance, especially for use in harsh climates.

A controller's worst enemies are heat and water. For a cargo vehicle that works hard all day, reliability is just as important as performance. When you're inspecting a controller, don't just read the label. Look for these physical signs of quality.

Pre-Purchase Reliability Checklist:

- Heat Sink Quality: Does it have a large, heavy aluminum body with deep fins? More surface area means better cooling. A controller that runs cool will last longer and perform more consistently. Avoid small, smooth plastic cases.

- Water and Dust Proofing: Are the wire connections sealed with rubber gaskets? Is there an IP rating (like IP65 or IP67) mentioned? If you operate in a region with heavy rain or dusty roads, this is a non-negotiable feature.

- Brand Reputation: Are you buying from a known brand, or is it a generic, unbranded unit? I always recommend using the controller brand that is officially paired with your motor or another reputable aftermarket brand. The quality of internal components like MOS tubes and capacitors can vary hugely between brands, even if the tube count is the same.

- Confirm the Amp Rating: Finally, always double-check the amp rating on the controller's sticker. This is the most important number. Make sure it provides that slight buffer over your motor's calculated needs to ensure it's not constantly running at its absolute limit.

Çözüm

Matching your e-rickshaw controller to the motor is a balance of science and practical planning. Start by matching the voltage and giving the motor enough amps, then choose a unit with the build quality to survive your local conditions.