Are you looking to enter the electric tuk tuk market but worried about finding a trustworthy supplier in China? You've heard stories of poor quality, missed deadlines, and disappearing contacts.

A bad tuk tuk supplier can ruin your investment and reputation. But with the right vetting process, you can find a reliable partner for long-term success. Following these four practical tips will help you separate professional manufacturers from risky trading companies and workshops.

From my position as a factory owner, I see importers make the same mistakes over and over. They get attracted by a low price but fail to check the supplier's background. A professional partnership is built on trust, transparency, and proven capability. It's not just about buying a product; it's about building a supply chain. Let me walk you through the same process I would use if I were in your shoes.

How can I verify an electric tuk tuk supplier’s credibility and certifications?

Feeling uncertain about a supplier's claims? A slick website doesn't guarantee a legitimate operation. You need proof, not just promises, to protect your business.

To verify a E-tuk supplier, demand to see their business license, ISO 9001 (quality management), and any market-specific certificates like CE. These documents prove they meet international standards and are a legitimate business.

Any genuine manufacturer will have their documents ready to share. If a supplier is hesitant to provide them, that is a major red flag. But don't just take the PDF file at face value. A little homework goes a long way.

First, I recommend doing some online research. Use Google to search for the company's name plus words like "review," "scam," or "dispute." Look them up on B2B platforms like Alibaba and check their verification status (e.g., "Verified Supplier" tag). This initial screening can filter out many bad actors.

Next, ask for the documents. Here is what you should request:

- Business License: Confirms they are a legally registered company in China.

- ISO 9001 Certificate: Shows they have a structured quality management system in place.

- CE Certificate: Essential if you are importing into Europe, as it confirms the product meets EU safety, health, and environmental requirements.

- Product-Specific Test Reports: For factors like battery life or load capacity.

The ultimate verification is a factory audit, either by visiting in person or hiring a third-party inspection agent. As a trusted electric tuk tuk exporter, we welcome these visits. Seeing the production line, meeting the team, and checking the paperwork firsthand is the best way to build real confidence.

What production capacity and quality standards should I expect from a tuk tuk manufacturer?

Concerned a supplier can't handle your order size? Worried that the quality of the 100th unit won't be as good as the first sample? You need to match the factory's capability to your business needs.

Look for a electric tuk manufacturer with a clear production capacity (e.g., 2000-3000 units/month) and a documented Quality Control (QC) process. This ensures they can meet your order deadlines and deliver consistent quality for every single vehicle.

Production capacity isn't just a number; it tells you about the supplier's stability and reliability. A small workshop might be good for a one-off custom job, but for a distributor needing a steady supply, you need a scalable factory.

You should ask potential suppliers about their QC process. Do they inspect incoming raw materials? Do they have quality checkpoints on the assembly line (e.g., for welding, painting, and electrical systems)? Do they perform a final test drive on every tuk tuk electric vehicle before packing? A professional factory will be proud to explain their QC system. For a product like an electric freight tuk tuk, the frame welding and load-bearing capacity are critical quality points to discuss.

Here’s a general guide to factory sizes:

| Factory Scale | Monthly Capacity | Quality Consistency | Melhor para |

|---|---|---|---|

| Small Workshop | < 100 units | Can be variable | Custom one-off projects, very small trial orders. |

| Medium Factory | 100 - 500 units | Bom | B2B Distributors, fleet operators, government projects. |

| Large Manufacturer | 500+ units | Muito alto | Major brand OEMs, large-scale national tenders. |

How do I assess a supplier’s delivery performance and after-sales service?

Afraid of shipping delays that will hurt your sales season? Worried about what happens if a vehicle has a problem and you need spare parts? The relationship doesn't end when the container ships.

Assess a electric tricycle supplier by reviewing their standard lead times, warranty policy, and spare parts availability. Reliable after-sales support is crucial for long-term operational success, not just the initial purchase.

A great product is useless without great support. Before you even place a trial order, you need to evaluate the supplier’s commitment to service. A good partner helps you succeed in your local electric tuk tuk market.

Here is a checklist to use when assessing a supplier:

- Lead Time: What is their standard production time for a 40ft container? How do they handle potential delays during peak season?

- Garantia: Do they offer at least a 12-month warranty on key components like the motor, controller, and frame? Is the policy clear and in writing?

- Peças de reposição: Can they provide a detailed spare parts catalog with prices? How quickly can they dispatch spare parts when you need them? This is vital for maintaining your fleet.

- Technical Support: Do they provide English assembly manuals, instruction videos, or have technical staff who can answer questions?

For example, whether you sell an electric tuk tuk scooter or a larger cargo model, you will eventually need replacement brake pads or tires. A supplier who can't easily provide them is not a long-term partner.

How can I reduce sourcing risks before committing to large orders?

Don't want to risk a large amount of capital on an unproven supplier? You can protect yourself with a smart, step-by-step approach that verifies everything before you scale up.

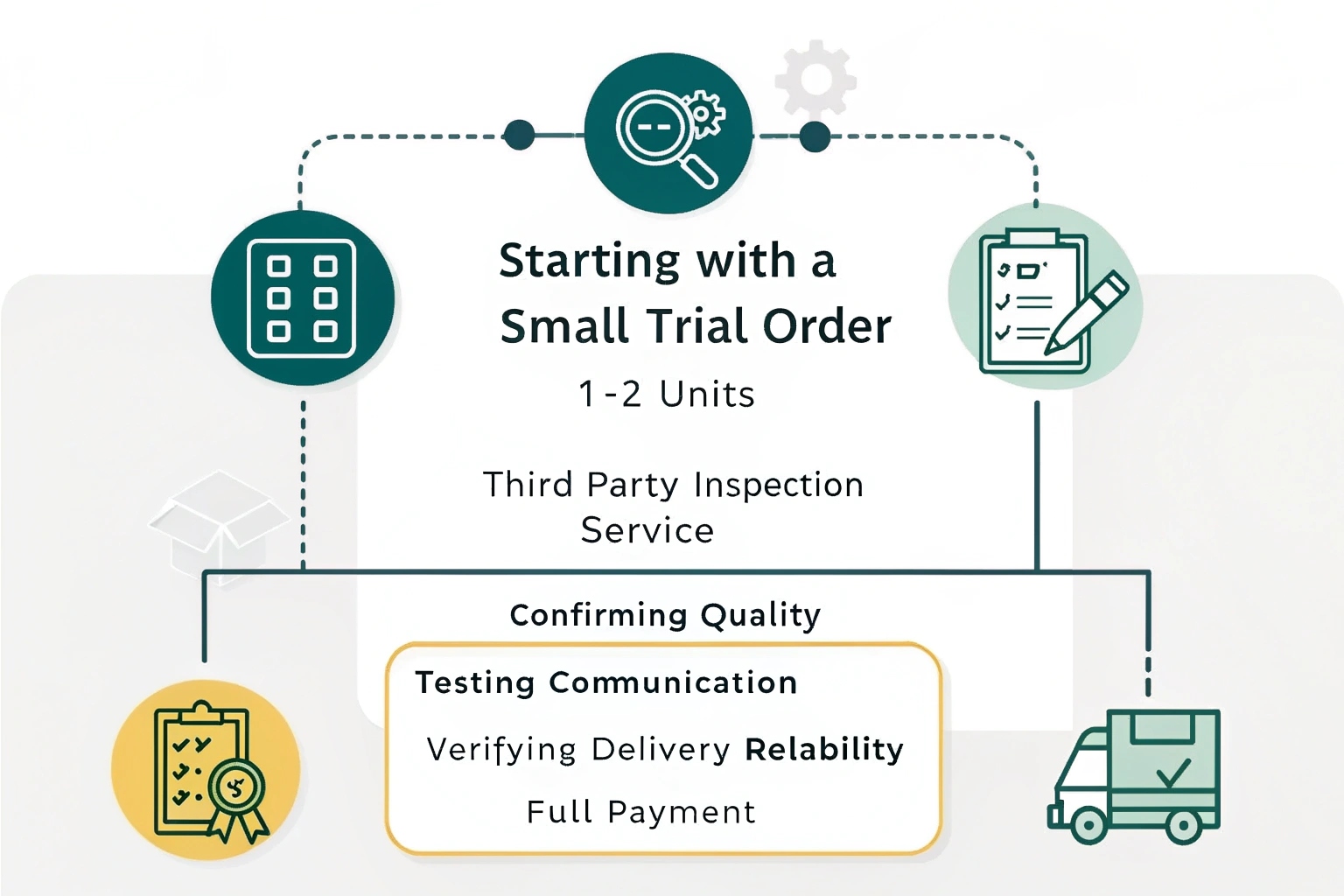

Always start with a small trial order (1-2 units) and use a third-party inspection service before final payment. This process lets you test the product quality, communication, and delivery reliability with minimal risk.

Jumping into a full container order with a new supplier is a gamble I would never recommend. The professional way to manage risk is to verify first, then scale. Every qualified electric tuk tuk exporter will understand and support this process.

Here is a simple risk management workflow to follow:

- Place a Small Trial Order: Order one or two sample units to be shipped. This allows you to test the vehicle in your local conditions.

- Confirm All Details on a Proforma Invoice (PI): Ensure the PI lists every specification: color, battery type, motor power, accessories, etc. This written document prevents future misunderstandings.

- Arrange Third-Party Inspection: Before you pay the final balance, hire an inspection company (like SGS, TUV, or QIMA) to go to the factory. They will check if the finished goods match your PI, verify quantities, and perform basic quality tests. It's a small cost for huge peace of mind.

- Use Safe Payment Terms: A standard, safe payment structure is a 30% deposit to start production and the 70% balance paid after the goods have passed inspection and you have received a copy of the Bill of Lading. Never pay 100% upfront to a new supplier.

By following this process, you confirm quality and reliability before committing to a full container, ensuring your large order is safe.

Conclusão

Choosing the right supplier comes down to four key actions: verifying credentials, assessing production capability, checking after-sales support, and managing risk with a trial order. This diligence protects your investment.