A customer's new electric tuk tuk is down, and your workshop is struggling to find the problem. Every minute they waste costs you both money and trust, damaging your brand's reputation.

Every distributor needs a core toolkit with basic hand tools, electrical testers, and specialized equipment. This setup is crucial for fast, professional after-sales service that builds customer loyalty and grows your business.

As an electric tricycle factory owner, I can tell you that selling the vehicle is only the first step. The most successful distributors I work with invest just as much in their service capabilities as they do in their showroom. They know that a strong after-sales program, powered by the right tools and trained technicians, is the key to dominating a market. An investment in your workshop is an investment in your brand's future. Let's look at what every professional service center should have on hand.

What Basic Hand Tools Are Essential for Electric Tuk Tuk Repairs?

A simple brake adjustment turns into a stripped bolt because your mechanic used the wrong wrench. This amateur mistake looks unprofessional and can turn a quick fix into an expensive part replacement.

Tuk Tuk Distributors need professional-grade wrenches, screwdrivers, pliers, and a torque wrench. These tools handle routine adjustments and small part replacements on any electric three-wheeler efficiently and safely.

Industry reports show that up to 70% of common breakdowns involve minor mechanical issues that are easy to fix with the right tools. Your workshop is the first line of defense. Having a quality set of hand tools is non-negotiable for any serious electric cargo tricycle business. It’s what separates a professional service center from a backyard mechanic. These tools are used daily for everything from initial assembly to routine maintenance and part replacements. A torque wrench, in particular, is critical for safety, ensuring wheel nuts and brake components are tightened to exact factory specifications.

- Metric Wrench and Socket Set: For all nuts and bolts on the frame, wheels, and suspension.

- Screwdriver Set (Phillips & Flathead): To access electrical component boxes, lights, and body panels.

- Pliers and Wire Strippers: Essential for adjusting cables and making clean wiring repairs.

- Tire Levers and Pressure Gauge: For fixing flat tires, a very common issue.

- Torque Wrench: Crucial for safety-critical tasks like tightening wheel lug nuts.

Which Electrical Testing Tools Should Distributors Keep in Stock?

An e-rickshaw is completely dead, but the battery seems fine. Your technician wastes hours guessing the cause, frustrating the customer and losing valuable service time.

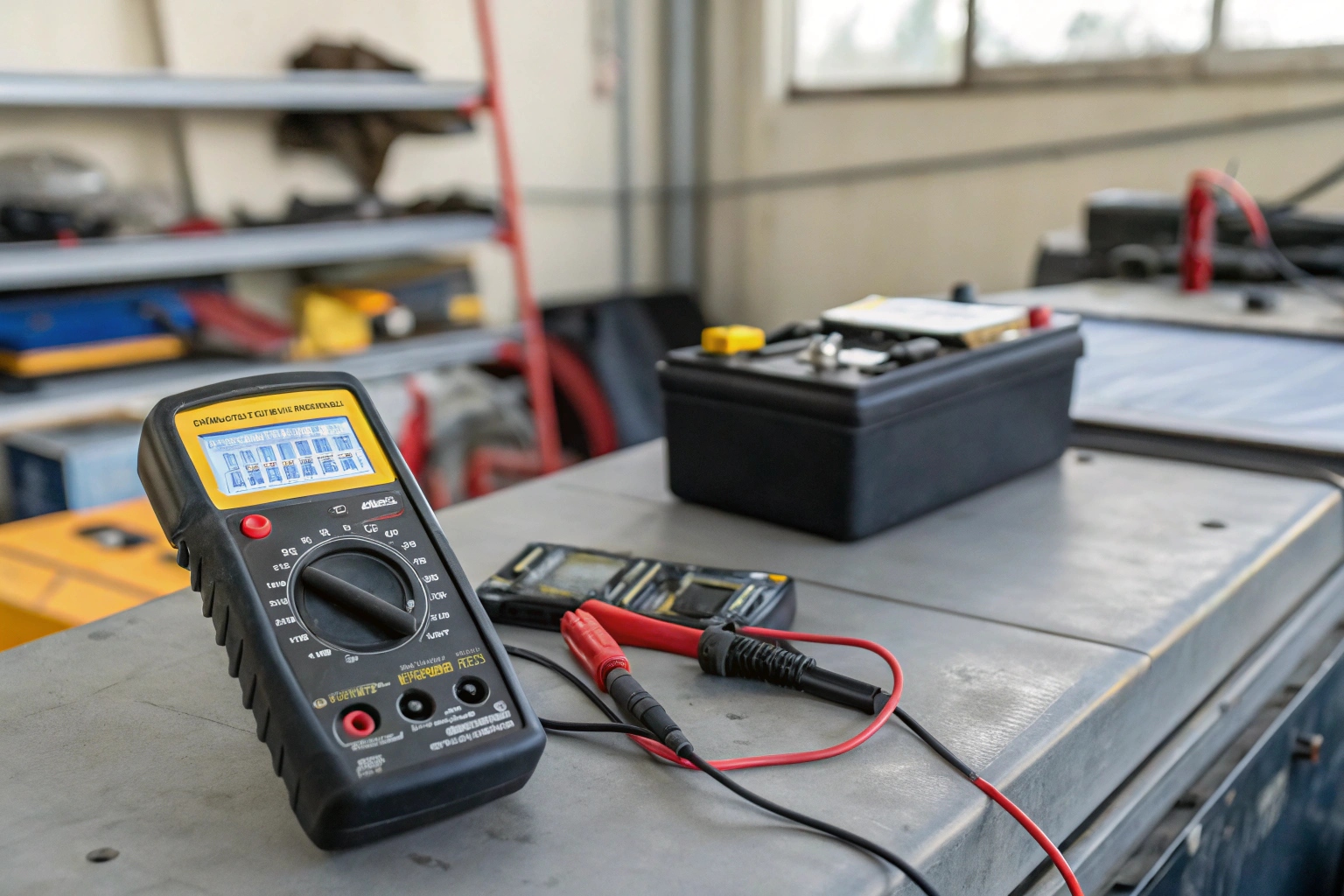

A digital multimeter and a battery tester are essential. These tools help your service team quickly find and fix electrical system faults in electric tuk tuks, from wiring to controllers.

Electrical issues can be intimidating, but with the right diagnostic tools, they become simple to solve. Given that battery or wiring problems are behind around 40% of EV service requests, you cannot afford to guess. These tools provide data, turning an invisible electrical problem into a clear, actionable insight. A Multimeter is the starting point for all electrical troubleshooting. For more advanced diagnostics, a bench power supply allows you to test individual components like horns or lights safely on your workshop table. Proper training on how to use these tools is vital to ensure technician safety and prevent damage to sensitive electronic components like the controller.

| Tool | Function | Common Repair Scenario |

|---|---|---|

| Digital Multimeter | Measures voltage, current, resistance, continuity. | Diagnosing a "no power" issue; finding a break in a wire. |

| DC Bench Power Supply | Provides stable DC power on the workbench. | Testing if a headlight or horn works before installing it. |

| Soldering Iron & Kit | Creates permanent, an electrical connection. | Repairing a broken wire or replacing a connector properly. |

Do Distributors Need Specialized Equipment for Battery and Motor Maintenance?

A customer insists their lithium battery is faulty. You need a way to prove its actual condition before approving a costly warranty replacement, as battery replacements can be up to 30% of EV parts costs.

Yes. Lifting stands for ergonomics, insulated tools for safety, and a battery diagnostic tester are crucial for professionally handling high-voltage lithium batteries and motors in electric tuk tuks.

The battery and motor are the most expensive components of an electric tricycle. Handling them requires more than just basic hand tools. Lithium batteries are heavy and operate at high voltages, creating risks of physical injury and electrical shorts if not handled correctly. A battery diagnostic tester is your most important specialized tool. It provides a definitive health report on a battery, allowing you to manage warranty claims with data, not opinions. When handling these core components, always follow safety protocols. If you face a complex motor or battery issue you can't diagnose, that's the time to contact me at the factory for support.

- Vehicle Lift or Stand: Safely raises the tricycle for easy access to the motor and battery tray.

- Insulated Hand Tools: A dedicated set of wrenches and screwdrivers with insulated handles prevents accidental short circuits.

- Battery Diagnostic Tester: Applies a load to the battery to measure its true health and capacity, essential for diagnostics.

How Can Stocking the Right Tools Improve a Distributor's After-Sales Service?

You're losing repeat business because customers are tired of long repair times and uncertain outcomes. This poor service reputation is starting to hurt your new vehicle sales.

Proper tools lead to faster repairs, happier customers, and fewer incorrect warranty claims. This builds credibility and drives repeat sales, turning your service center into a profit center.

The link between your toolkit and your bottom line is direct. Surveys show that 67% of B2B buyers consider reliable after-sales service a top factor when choosing a supplier. Investing in the right tools gives you a powerful competitive advantage and impacts your business in several key ways:

- Faster Repair Times: Diagnostic tools pinpoint problems in minutes, not hours, increasing your workshop's daily capacity.

- Stronger Brand Reputation: Professional, efficient service builds trust and word-of-mouth marketing.

- Higher Service Margins: Accurate diagnostics prevent you from replacing expensive parts unnecessarily, protecting your profits.

- Increased Customer Loyalty: Customers whose vehicles are fixed quickly and correctly are far more likely to buy from you again.

Your workshop isn't a cost center; it's one of your most effective sales and marketing assets.

Konklusyon

Equipping your workshop with the right tools is a foundational investment. It directly improves your efficiency, profitability, and brand reputation in the competitive electric mobility market.