Sourcing in bulk is risky. A bad supplier means faulty products, lost capital, and a damaged reputation. A clear vetting process is essential for finding a trustworthy partner.

When sourcing mobility scooters in bulk, you must verify quality certifications , evaluate the supplier's manufacturing capacity and reliability, plan for logistics and shipping challenges, and negotiate fair pricing and payment terms.

Before you even think about placing a bulk order, you must know exactly what kind of scooter your market needs. If you haven't done that yet, I suggest reading my previous article on how to choose the right mobility scooter for your target market. Once you have a clear product specification, the next step is finding the right factory to build it for you. This is where many importers make costly mistakes. Let's break down how to get it right.

What Quality Standards and Certifications Should You Verify When Choosing a Mobility Scooter Supplier?

Skipping on certifications seems cheaper, but it’s a big gamble. Your shipment could be seized by customs, or you could face liability claims. Verifying standards protects your business.

Key certifications are CE marking for Europe and FDA registration for the United States,which shows a supplier's commitment to consistent quality and safety.

These are not just logos on a brochure; they represent a factory’s ability to meet critical safety and manufacturing standards. I often get asked by clients, “Do I really need this?” The answer depends entirely on your target market. If you plan to sell in Europe, a tanda CE is non-negotiable. It proves the product meets the EU’s safety, health, and environmental requirements. Importing without it is impossible. For the U.S. market, the bar is even higher. Mobility scooters are considered Class II Medical Devices by the FDA, and the supplier must be registered with them. Not every factory in China has this.

Key Certifications by Market

| Certification | Target Market(s) | What It Means for You |

|---|---|---|

| CE Marking | European Union (EU) | Your product meets EU safety standards. Essential for market access. |

| FDA Registration | United States (USA) | The supplier is registered to produce Class II Medical Devices. Mandatory for US import. |

How Do You Evaluate Supplier Reliability and Manufacturing Capacity for Large Orders?

A slick website can hide a small, unreliable operation. Placing a large order with them can lead to major delays and poor quality. You must verify their real manufacturing capabilities.

Evaluate a supplier by checking their factory's production lines, quality control systems, and past performance with large orders. Ask for their Minimum Order Quantity (MOQ) and production lead times to see if they match your business needs. This confirms they can deliver consistently.

It’s crucial to tell the difference between a real factory and a trading company. A trading company might offer a lower price, but they don’t control production, which often leads to inconsistent quality and longer lead times. As a real factory, we always encourage potential partners to look deeper. Ask for a virtual factory tour. See the assembly lines, the testing equipment, and the warehouse. We had a client who almost signed with a “supplier” who kept making excuses to avoid a video call. It turned out to be a small office with no factory at all. He avoided a disaster.

You need to ask direct questions that a trading company can’t easily answer. “What is your monthly output for this model?” “Can you show me a QC report from the last production run?” “What is your process for handling defects?” A reliable factory will have clear answers and documentation. Also, discuss their OEM/ODM capabilities. If you want to build your own brand, you need a partner who can customize products, not just ship a standard model.

What Are the Key Logistics and Shipping Considerations for Bulk Mobility Scooter Orders?

Your order is ready, but the logistics are a nightmare. Battery regulations and customs can trap your shipment, racking up fees. Planning your shipping strategy early is critical for success.

The biggest consideration is battery shipping. Lithium and lead-acid batteries have different regulations. You also must consider packaging for protection, container optimization (CKD/SKD), insurance, and customs documentation to ensure a smooth import process.

From my experience, batteries are the number one headache for new importers. They are classified differently for shipping. Lead-acid batteries are heavy but are usually considered “non-dangerous goods.” Lithium-ion batteries are much lighter but are classified as “dangerous goods.” They require special U38.3[^1] testing and certification (an MSDS, or Material Safety Data Sheet) to be shipped legally by sea or air. A good supplier will have all this documentation ready for you. If a potential supplier doesn’t know what UN38.3 is, that’s a major red flag.

Another key area is how the scooters are packed. Shipping them fully assembled takes up a lot of space in a container. We often work with clients on an SKD (Semi-Knocked Down)[^2] or CKD (Completely Knocked Down) basis. This means we ship the scooters in parts. It allows you to fit many more units into a single container, which dramatically lowers your per-unit shipping cost. It does require you to have some local assembly capability, but the savings can be huge.

Shipping Options: SKD vs. Fully Assembled

| Shipping Method | Container Space | Shipping Cost per Unit | Buyer Requirement |

|---|---|---|---|

| Fully Assembled | Tinggi | Lebih tinggi | Unbox and sell |

| SKD/CKD | Rendah | Lebih rendah | Local assembly capability |

How Should You Structure Pricing and Payment Terms for Bulk Mobility Scooter Purchases?

Focusing only on the lowest unit price is tempting. But restrictive payment terms and no after-sales support can cripple your cash flow. Negotiate the total value, not just the price.

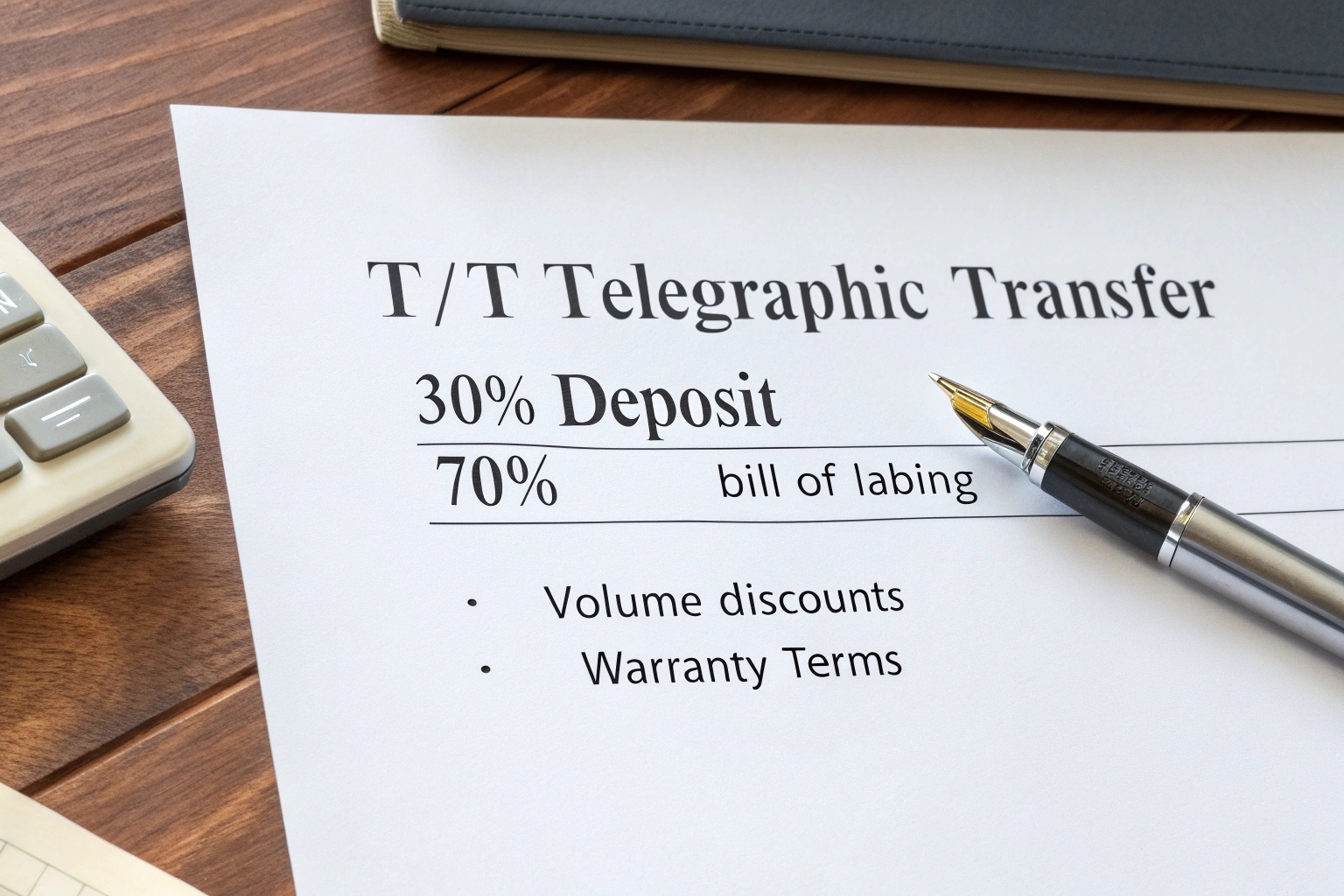

A standard structure is T/T (Telegraphic Transfer) with a 30% deposit to start production and the 70% balance paid before shipping or against the Bill of Lading copy. Negotiate volume discounts, but also secure clear warranty terms.

The most common payment term in our industry is a T/T, or wire transfer. The typical split is 30% upfront and 70% for the balance. The 30% deposit gives the factory the security to purchase raw materials and start production. The 70% balance is usually paid once production is finished and the goods have passed inspection, often before they are loaded for shipping. Some suppliers ask for the balance before shipping, while others will accept it after you receive a copy of the Bill of Lading (the document that proves the goods are on the ship). This is a key point of negotiation. For larger orders or new relationships, a Letter of Credit (L/C) can be used. It’s much more secure for both sides but involves more bank fees and paperwork.

But your negotiation shouldn’t stop at the payment schedule. A good partner is willing to discuss the total package. Ask about the warranty. What is covered and for how long? A one-year warranty on the battery and two years on the frame is a good starting point. Can they include a small percentage of free spare parts with your first order? This can save you a lot of time and money later. A good deal is about building a profitable partnership, not just a one-time transaction.

Kesimpulan

Sourcing scooters in bulk requires more than a low price. Diligent verification of quality, capacity, logistics, and payment terms is essential to building a profitable, long-term importing business.