You bought an electric pickup truck, but it keeps running out of power mid-delivery. Or worse, you overspent on a huge battery you don't even need, hurting your profit.

The key is to strategically match the battery's voltage (V) and capacity (Ah) to your business's average daily route distance, payload, and local terrain. This ensures you have enough range without paying for excess capacity you'll never use, optimizing both cost and performance.

From my factory floor, the most common and costly mistake I see importers make is guessing the battery specs. A battery isn't just a power source; it's the heart of your vehicle's business case. Choosing the wrong one leads to delivery failures, driver anxiety, and operational chaos. We offer over a dozen different battery configurations for a reason—each one is a tool for a specific job. Let's dive into our real-world data to help you choose the perfect match.

How Does Battery Capacity Affect an Electric 3 Wheel Pickup Truck’s Delivery Range?

You assume that a bigger battery is always the better choice for your electric truck. But this thinking adds unnecessary weight and drives up your initial investment, limiting your profitability from day one.

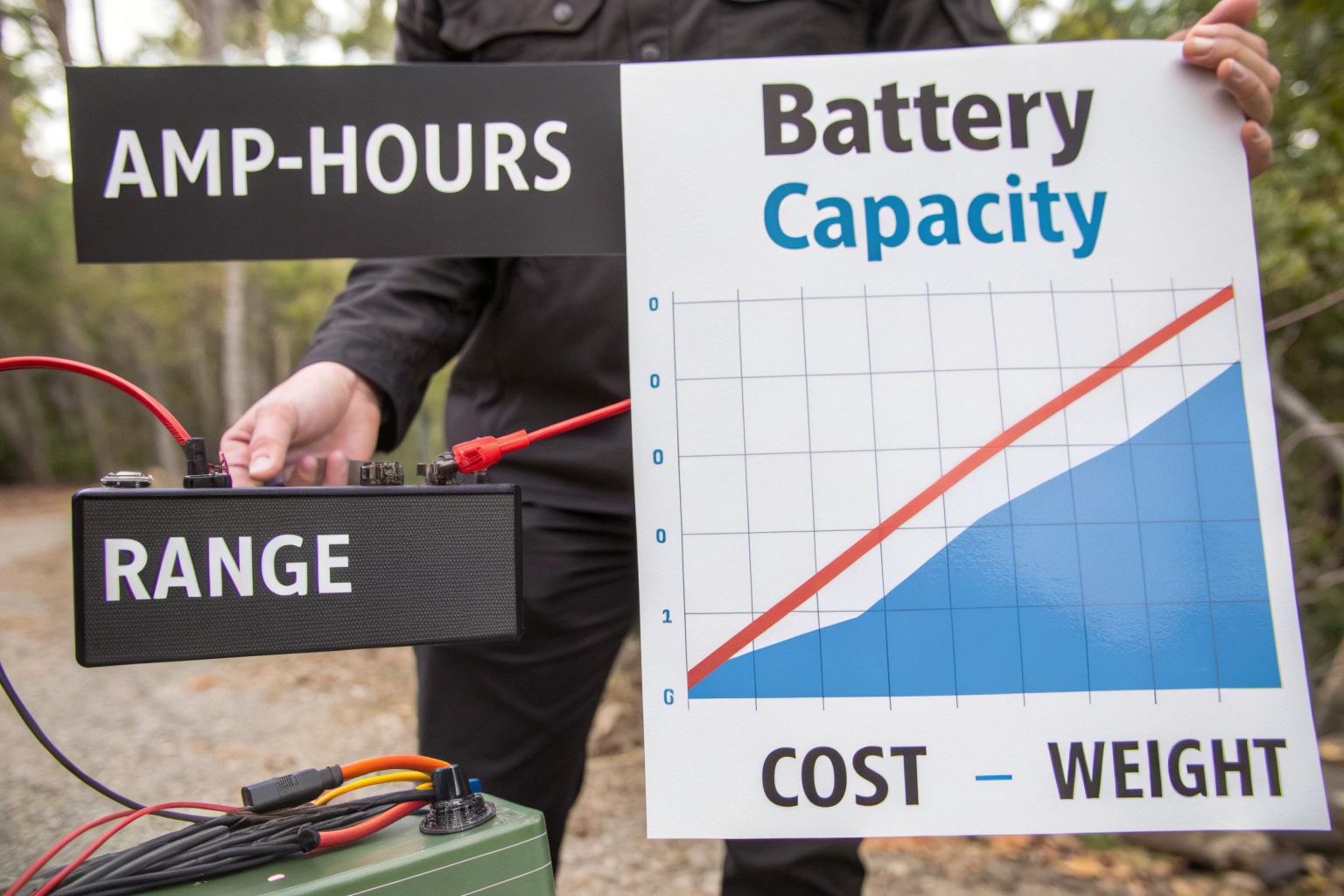

Higher capacity (Ah) directly increases the potential range but also adds significant cost and weight. The best choice is a balance based on your actual route length, not just buying the biggest battery available.

When clients look at our spec sheet, they see a lot of numbers. It's important to understand what they mean. Voltage (V) is like the motor's horsepower—higher voltage helps with heavier loads and hills. Amp-hours (Ah) is like the size of the fuel tank—more Ah means longer range. But bigger isn't always better. Let's compare some of our most popular lithium battery models.

| Battery Model | Ideal Range (Approx.) | Kasus penggunaan terbaik |

|---|---|---|

| 48V 60A | 45 km (approx. 28 miles) | Excellent for short, dense urban routes like food delivery. |

| 60V 60A | 55 km (approx. 34 miles) | A solid entry-point for general-purpose deliveries. |

| 60V 100A | 110 km (approx. 68 miles) | Our most popular "all-rounder" for mixed daily routes. |

| 72V 80A | 95 km (approx. 59 miles) | Great power for medium routes with frequent hills. |

| 72V 150A | 160 km (approx. 100 miles) | For dedicated long-distance routes between towns. |

| 72V 300A | 290 km (approx. 180 miles) | Extreme range for specialized long-haul logistics. |

What’s the Best Battery Size for Short, Medium, and Long Daily Routes?

You have different delivery routes but are unsure which battery fits each one. Using the same large battery for all routes is inefficient and costly, especially for short, frequent trips inside a community.

Match the specific battery model to your route category for maximum cost-efficiency. Analyze your business needs first, then select the battery that meets those needs with a small buffer.

The smartest fleet managers I work with don't use a one-size-fits-all approach. They match the vehicle to the job. A lightweight 3 wheel pickup for a coffee delivery business has very different needs than a tricycle truck hauling construction materials. By outfitting your vehicles with the right battery from the start, you optimize your entire operation for profitability. Here’s a guide to matching our battery models to specific business scenarios.

| Business Use Case | Daily Route Profile | Recommended Battery Model(s) | Mengapa itu berhasil |

|---|---|---|---|

| Urban Food Delivery | < 35 km (approx. 22 miles) | 48V*60A atau 60V*35A |

Low upfront cost, fast charging, lightweight. |

| E-commerce Parcels | 30 - 80 km (approx. 19 - 50 miles) | 60V*80A atau 60V*100A |

The perfect balance of range, cost, and capacity. |

| Hardware & Light Construction | < 50 km (approx. 31 miles) | 72V*80A atau 72V*100A |

The 72V system provides the extra torque needed. |

| Inter-Town Distribution | > 100 km (approx. 62 miles) | 60V*150A atau 72V*150A |

High capacity (Ah) is prioritized for maximum range. |

How Do Payload and Terrain Impact the Real-World Delivery Range?

The advertised range of your electric truck is 110 km (approx. 68 miles), but you're barely getting 70 km (approx. 43 miles) in the real world. Your delivery planning is unreliable.

Heavier payloads and hilly terrain are the top two factors that reduce range. Expect a 10–30% decrease in distance, which means you need to factor in a buffer when choosing your battery.

This is the most important lesson I teach new buyers: the "reference range" on any spec sheet is tested under ideal conditions. Your business operates in the real world. Every kilogram you add and every hill your driver climbs demands more energy. Let's compare how two different batteries—our all-rounder 60V*100A and our heavy-duty 72V*100A—perform under stress. The 72V system's higher voltage makes it more efficient under load.

| Operating Condition | Range w/ 60V*100A |

Range w/ 72V*100A |

|---|---|---|

| Ideal: Empty, Flat Ground | ~110 km (approx. 68 miles) | ~120 km (approx. 75 miles) |

| Medium Load: 300kg, Flat | ~93 km (approx. 58 miles) | ~105 km (approx. 65 miles) |

| Heavy Load: 500kg, Flat | ~82 km (approx. 51 miles) | ~95 km (approx. 59 miles) |

| Heavy Load + Hilly Terrain | ~70 km (approx. 43 miles) | ~84 km (approx. 52 miles) |

Notice how the 72V*100A battery maintains more of its range under heavy load. If your routes are tough, investing in the higher voltage system pays off.

How Should You Choose the Right Battery for an Electric Pickup Truck Fleet?

You are managing a fleet of electric tuk tuk vehicles with different batteries. This creates a maintenance nightmare with too many types of spare parts and unpredictable vehicle performance across the fleet.

Analyze all your daily routes, average payloads, and charging schedules to standardize on one or two battery specifications. This simplifies maintenance, reduces spare parts inventory, and lowers your total cost of ownership.

For B2B distributors and fleet operators, standardization is the key to profitability. Managing a dozen different battery types is a hidden cost that drains resources. After analyzing your data, you might find 80% of your routes are under 80km (approx. 50 miles) with moderate loads. In this case, standardizing your main fleet on our workhorse 60V*100A battery is a smart move. You can then keep a few 72V*150A trucks for those specific long-haul jobs.

Here is the process:

- Assess Your Needs: Track the daily distance and average payload for every vehicle.

- Analyze the Data: Identify your most common route profile.

- Select & Standardize: Choose a primary battery (e.g.,

60V*100A) for the bulk of your fleet. Add a secondary, heavy-duty spec (e.g.,72V*100A) only if required for a minority of tough routes. - Calculate Total Cost: By standardizing, you reduce costs for procurement, simplify spare parts inventory, and make maintenance training easier.

Kesimpulan

Choosing the right battery is a strategic business decision. Use real data from your routes to select the specific model that builds an efficient, reliable, and profitable delivery fleet for you.